6 Working Tips For A Better MIG Wire Welding

AWS D1.1 code provides recommended weld root dimensions for various weld joints configurations from Figure 5.1 and figure 5.2.Other references for recommended weld root gap, root face can be found in CSA W59, EN 1708 and EN15085-3 standards.. Weld Root Opening. Weld root opening (also called Root Gap) is one of the most important factors in welding.It is the space between the two pieces of.

Part 3 Teori pengelasan (welding), berbagai macam metode, tegangan residu, dan simulasi FEA

Dalam standarisasi ASME B36.19, metode pipa yang digunakan berjenis welded dan seamless. Welded artinya "dilas" sehingga pipa yang dibuat dengan metode ini tentu melewati proses pengelasan yang bermacam-macam. Metode ini menghasilkan kekuatan yang bagus untuk berbagai jenis kondisi lingkungan kerja.

Worker Welding Free Stock Photo Public Domain Pictures

Welding refers to a fabrication process that causes coalescence between materials such as metals, thermoplastics, and others. In welding, heat is used to melt the workpieces, and a filler material is used to form a weld pool or molten material. When the weld pool solidifies, a strong joint will be formed. Welding is an important process for the.

The Complete Guide to Full Welding WelderStream

The effects of post weld artificial aging and water cooling on the hardness profiles of the joints at 800 rpm-200 mm/min, 1200 rpm-200 mm/min and 1200 rpm-50 mm/min are shown in Fig. 6 (b-d), respectively. Overall, post weld artificial aging leads to considerable increase in hardness throughout the weld.

Gas tungsten arc welding Wikipedia

WELDING: Arti, Jenis dan Cara Kerjanya SUPRAPTO Senin, Oktober 19, 2020 Posting Komentar Welding, mengelas, adalah pekerjaan menyambung logam menggunakan panas. Di atas kapal welding atau pengelasan sering diperlukan. Pengelasan dibutuhkan baik dalam perawatan atau perbaikan bagian-bagian tertentu. Misalnya :

Advantages And Disadvantages Of Welded Connections Engineering Discoveries

Secara singkat, perbedaan pipa welded dan pipa seamless berada pada kelim yang ada di badan pipa. Pipa welded, atau dalam bahasa Indonesia disebut dengan pipa las, adalah pipa besi yang diproses dengan metode pengelasan. Pipa welded biasa dibuat dari plat atau strip baja yang disambung dengan teknik las. Sambungan dari pipa welded ini pun.

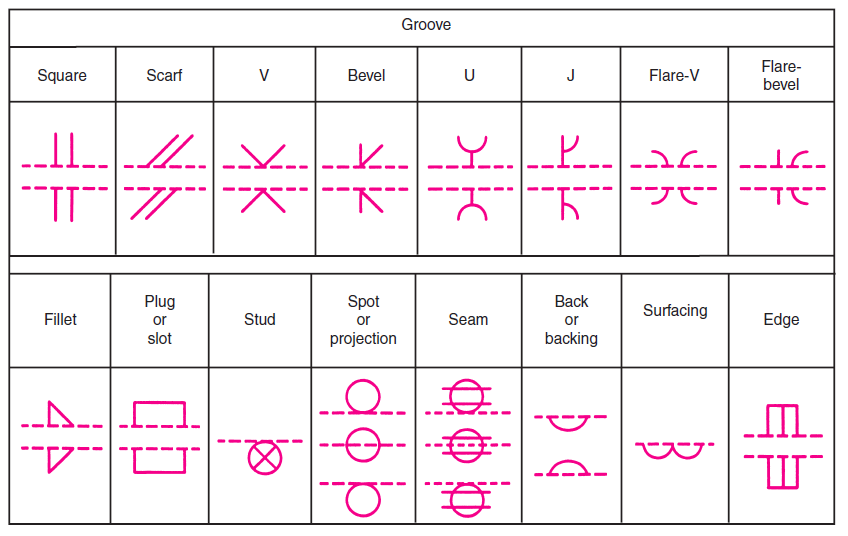

Weld Joints and weld symbols Types of Weld

Berdasarkan metode pembuatannya, proses pembuatan pipa welded dapat dibedakan menjadi berikut ini. Daftar Isi. ER/EF/HF Welding. Electric Resistance Welding (ERW) Electro Fusion Welding (EFW) High-Frequency Welding (HFW) Submerged Arc Welding (SAW) Pipa Las Spiral (Spiral SAW Welded Pipe) Pipa Las Lurus/Longitudinal (Straight SAW Welded Pipe)

Welding PerfoLux Metal Fabrication

Permukaan akhir yang lebih baik pada bagian luar-dalam pipa. Konsistensi dan toleransi ukuran lebih pasti dan tepat. Jadi kesimpulannya perbedaan yang sangat mencolok antara pipa seamless dan pipa welded terletak pada proses produksinya. Kalau pipa welded menggunakan sambungan sedangkan pipa seamless tanpa sambungan.

Stainless Steel Welding & Fabrication Heavy Metal Supply Heavy Metal Supply

1. Perbedaan Pipa Welded dan Seamless Berdasarkan Fungsinya. Bila dilihat dari sifatnya, pipa welded terbilang lebih rentan terhadap suhu tinggi karena proses pembuatannya menggunakan sambungan las. Bekas pengelasan itulah yang dapat menimbulkan kobocoran jika digunakan dalam frekuensi berlebih. Karenanya, pipa welded kerap digunakan untuk.

what is welding

Girth welding is the process of connecting two pipes by welding around their circumference. As the welding is done around the pipe circumferences, girth welding is also popular as circumferential welding. Several welding passes are required to create a proper weld joint. The most widespread application of girth weld is found to join pipe and.

Man Welding Metal Bars · Free Stock Photo

This means that the as-welded state is the final condition of the weld metal and weldments before any fabrication steps are carried out. The as-welded state of the weld metal can be affected by a number of factors, such as: and the welding parameters employed. These factors can all influence the microstructure and properties of the resulting.

Gambar kerja, menghasilkan, pengelasan, pabrik, pekerja, palet, harihari, arc welding

Istilah-istilah pengelasan welder wajib paham. Bambang Hari Nugroho, ST. in Pengelasan. Di dunia pengelasan sering kali digunakan istilah istilah pengelasan yang berasal dari bahasa asing. Dimana istilah tersebut dipakai secara luas untuk kesamaan pemahaman atau acuan dalam suatu standar pengelasan. istilah pengelasan itu mencakup pada proses.

Easy Guide to Welding Symbols

Itu artinya memiliki kekuatan luluh (yield strength) 423 MPa, ultimate strength 470 MPa dan modulus elastisitas 225 GPa.. Pipa baja CS atau SS mempunyai dua tipe yakni seamless dan welded. Jika Anda mencari pipa seamless, perhatikan permukaan bagian insidenya apa itu jenis pipa seamless atau welded sesuai yang Anda inginkan.

What is Tack Welding? Understanding it Thoroughly WaterWelders

In as-welded state, each region of 2219 aluminum alloy TIG-welded joint shows different microstructure and microhardness due to the different welding heat cycles and the resulting evolution of second phases. After the post-weld heat treatment, both the amount and the size of the eutectic structure or θ phases decreased. Correspondingly, both the Cu content in α-Al matrix and the.

Welded beams Metest Steel OÜ

weld artinya dan weld adalah : [ weld ] memateri…. klik untuk terjemahan Inggris ke bahasa Indonesia

Gas tungsten arc welding Wikipedia

Evaluating Tube-to-Tubesheet Welding Types. Design engineers have basically two weld options for a tube-to-tubesheet joint: 1) roll or expand (with grooves milled in tube holes) and seal welded, or, 2) strength welds (no grooves required). Each type of joint has advantages and disadvantages; regardless of which type you choose, it's crucial.