Vertical clarifier DBC Roytec Global

A prototype radial/vertical clarifier with 60° cone bottom was built and evaluated for application in recirculating aquaculture. Samples were analyzed for particle size distribution using a laser diffraction particle analyzer (Mastersizer S, Malvern Instruments Ltd., Worcestershire, UK) and total suspended solids (TSS) to determine the effectiveness of the clarifier.

Vertical_Clarifier_SS Kappe Associates, Inc

Clarifiers are designed for a weir overflow rate of 10,000 to 20,000 gpd/ft. The weir overflow rate can be determined by: Using the same clarifier as the last two examples: Example: A round clarifier handles a flow of 1.8 MGD and has a suspended solids concentration of 3,800 mg/L. The clarifier is 45 feet in diameter and has a depth of 9 feet.

Vertical clarifier FB series FRACCAROLI & BALZAN S.p.a

It considers some of the practical aspects of clarifier selection and design and some of the various types of clarifier in more detail. There are two basic types of settling basins: horizontal flow and vertical flow; and two other types of clarifiers: vertical-flow solids contact tanks; and DAF tanks. First horizontal- and vertical-flow tanks.

Lamella Plate Vertical Clarifier Monroe Environmental

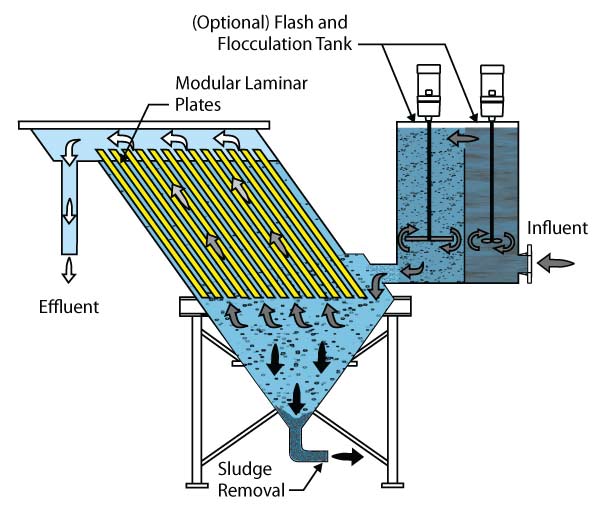

Lamella Clarifier. The Lamella ® is the original inclined plate clarifier. Introduced by Parkson in 1971, it has been the industry standard for this technology. How It Works. The Lamella clarifier works when a solid/liquid stream that has been flocculated, enters a tank, and flows upward between a pack of inclined plates.

China Lamella Plate Vertical Clarifier Manufacturers, Factory Customized Lamella Plate

Vertical Plate Clarifiers: Retrofit at a Catalyst Plant Rebuild for Under-Performing Clarifiers A chemical plant had two under-performing lamella plate clarifiers with internal components that were warped, buckling, and in danger of collapsing. The plate supports, separation walls, and structural members were inadequate for supporting the internals

Lame Duck Lamella Plate Vertical Clarifier Dengan Flocculant Ke Pemisah Untuk Pengolahan

Roytec is the leading supplier of Pin Bed Clarifiers (PBC's) and Dynamic Bed Clarifiers (DBC's) globally, with many units installed in Southern Africa and Internationally. BC's and DBC's are used for the clarification of river water or on any process stream, typically Pregnant Liquor Solution (PLS). High filtration fluxes - 7 to 10m³.

Vertical clarifier / plate RITM Industry

Vertical Flow Clarifier We will complete the same exercise for vertical flow clarifiers shown in Fig. 159. In vertical flow clarifiers, water flows up from the bottom of the reactor and exits near the top of the reactor. Fig. 159 Vertical flow clarifier. 1) How much time is required for water to pass through the tank?

Lamella Plate Vertical Clarifier Monroe Environmental

Our History. St Mary's current building was built in 1230AD, and there are references to a church on the site back to the Doomsday book in 1086.

Lamella Plate Vertical Clarifier Monroe Environmental

vertical clarifier. DBC. Roytec is the leading supplier of Pin Bed Clarifiers (PBC's) and Dynamic Bed Clarifiers (DBC's) globally, with many units installed in Southern Africa and Internationally. BC's and DBC's are used for.

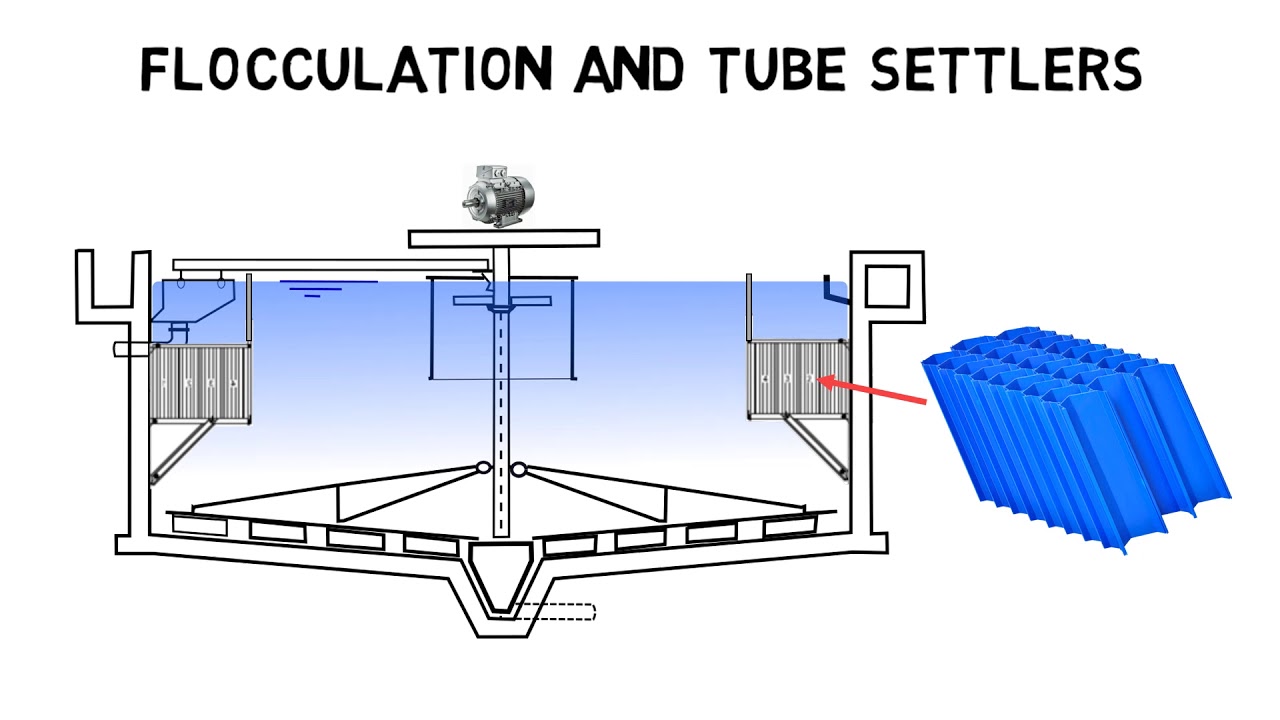

Flocculating Clarifiers

The scraper mechanism arms rotate slowly along the clarifiers perimeter and are attached to a centrally located shaft which is powered by a drive system on the clarifier bridge. The removed sludge will either by recycled as RAS (return activated sludge) or wasted as WAS (waste activated sludge). The clarified water instead is released over.

Cav Art Tailored plants and machines vertical clarifiers

Vertical parallel plate clarifiers operate using the same laminar flow principle, but the liquid flows vertically. The influent flows to the lower area of the laminar plate sections. Waste fluid flows up the plates under laminar conditions, and then particulates settle onto the plates and slide down to the removal area.

» Clarifiers

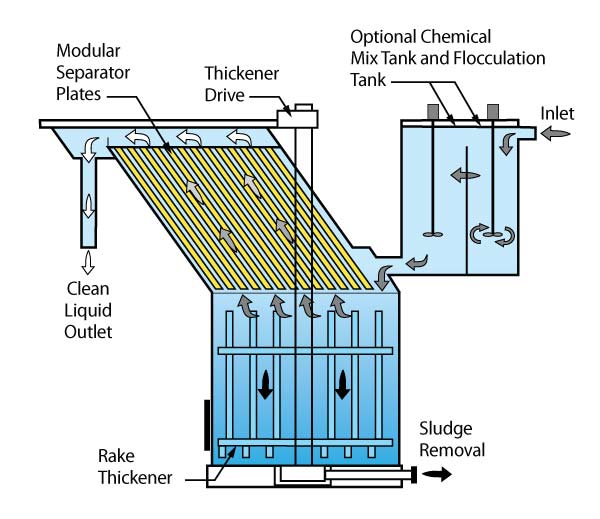

The Monroe Environmental® Vertical Clarifier is designed to provide low cost, eficient solids removal from a wide range of waste and process liquids. The inclined plate design allows the total gravity settling area to be as much as ten times more than the actual floor space oc-cupied by the clarifier. Integral chemical mixing and flocculation.

Clarifier basics How do clarifiers work I Clarifier design YouTube

Clarifier to a vertical depth of approximately 2 meters (6 feet). The distance between the. individual plates is between 40 and 120 mm (1.6 to 4.8 inches).

Lamella Plate Vertical Clarifier Monroe Environmental

Paralle - Vertical Plate Clarifier. The Monroe Parallel Plate Vertical Clarifier is designed to provide low cost, efficient solids removal from a wide range of waste and process liquids. The inclined plate design allows the total gravity settling area to be as much as ten times more than the actual floor space occupied by the clarifier.

Lamella Plate Vertical Clarifier Monroe Environmental

One of two Lamella Plate Vertical Clarifiers provided for an automotive plant's wastewater treatment system. Scope of supply included two clarifiers, stainless steel construction with separator plates, integral thickeners, drive mechanisms, pre-treatment tanks with mixers, PLC controls, access platforms, walkways, and PLC controls.

Lamella Plate Vertical Clarifier Monroe Environmental

Fraccaroli e Balzan offers vertical clarifiers and high rate thickeners, with a treatment capacity from 100 lt/min to 41.000 lt/min. Plants can be controlled from remote station. Static decanters are vertical. High rate thickeners can have a circular or rectangular cross section, they are suitable for very high flow rates and used in mining and aggregates washing plants.