Explore Porous Sparger Uses and Types with Saifilter.

Arti kata sparger adalah semprot. Arti lainnya dari sparger adalah semprotan. KI I. Lektur GadgetLogi TTSave KBBI Antonim Sinonim Cek Typo. 3 Arti Kata Sparger di Kamus Bahasa Inggris Terjemahan Indonesia. Terdapat 3 arti kata 'sparger' di Kamus Bahasa Inggris Terjemahan Indonesia. Sparger Nomina (kata benda) Semprot;

proses fermentasi Aeroengineering.co.id

Saifilter Sparger Pipe is an industrial device used to introduce gases into liquids, facilitating aeration or gas dispersion in processes like fermentation, bioreactors, or chemical reactions. The Porous Sparger, in particular, offers superior distribution and smaller bubble formation, increasing the efficiency of gas-to-liquid contact.By releasing fine bubbles into the liquid, sparger pipes.

PM Sparger GKN Sinter Metals

Assume a sparger diameter. Calculate liquid linear velocity in the annulus between the pipe line ID and the sparger element ID.** Select Gas Exit Velocity FPM. 10. 11. Calculate sparger area required Ft2 (A). A = ACFM FPM Select the appropriate Mott sparger element. A reinforced element, or an element with a centering spider for support within.

Types Of Sparger In Fermenter Design Talk

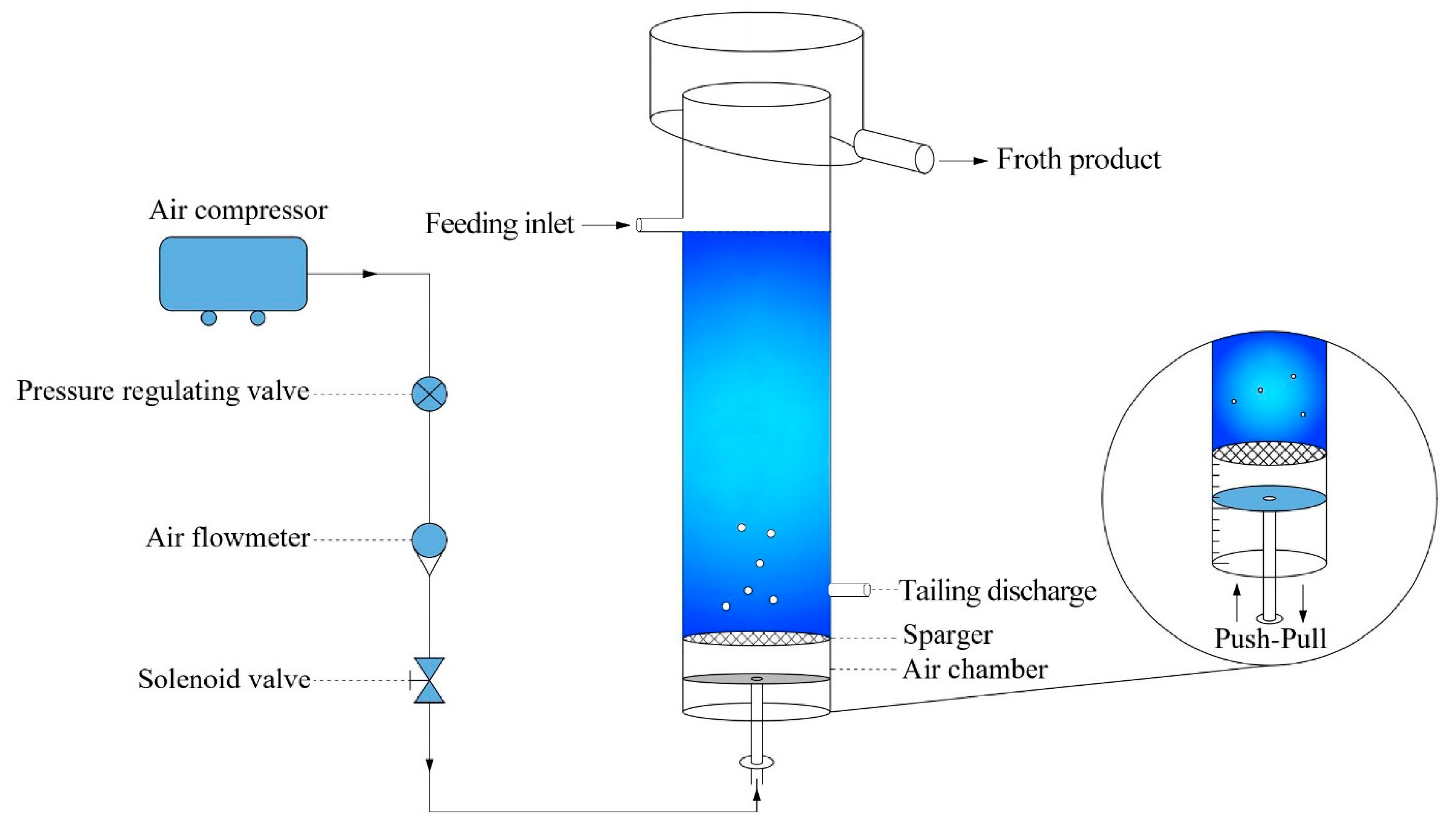

A bubble column reactor is a chemical reactor that belongs to the general class of multiphase reactors, which consists of three main categories: trickle bed reactor (fixed or packed bed), fluidized bed reactor, and bubble column reactor. [1] A bubble column reactor is a very simple device consisting of a vertical vessel filled with water with a.

What is Sparging? Altitude Brewing & Supply

A basic understanding of mass transfer and its underlying principles is essential to single-use bioreactor design, determining bioreactor operating parameters, and optimizing culture conditions. This paper aims to elucidate the standard mass transfer model, and details how the application of critical mass transfer principles to the design and.

Difference Between Spargers in Gas/Liquid Dispersion YouTube

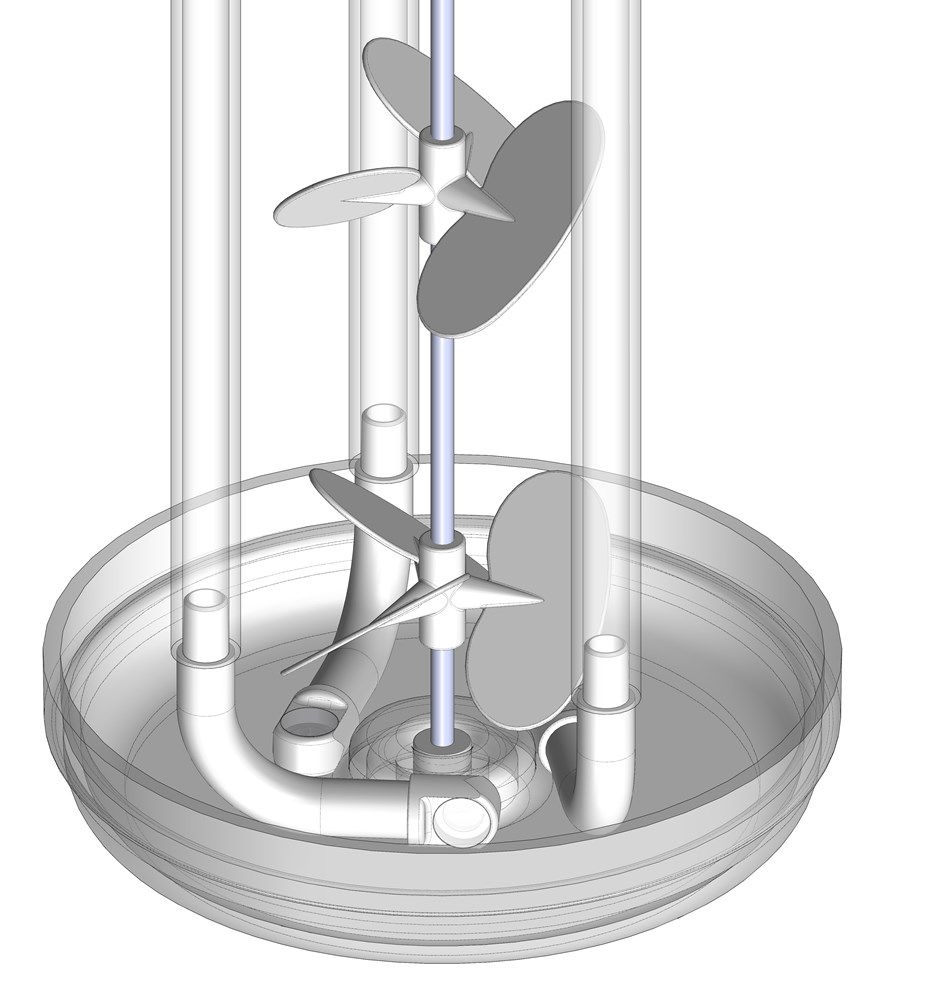

The sparger, in combination with impellers (agitators), allows for improved gas distribution throughout the vessel. A stirred tank bioreactor can be operated continuously in the fermentor, temperature control is effortless, construction is cheap, easy to operate, resulting in low labor cost, and it is easy to clean. It is the most common type.

Processes Free FullText Role of Sparger Configuration in Determining Flotation Performance

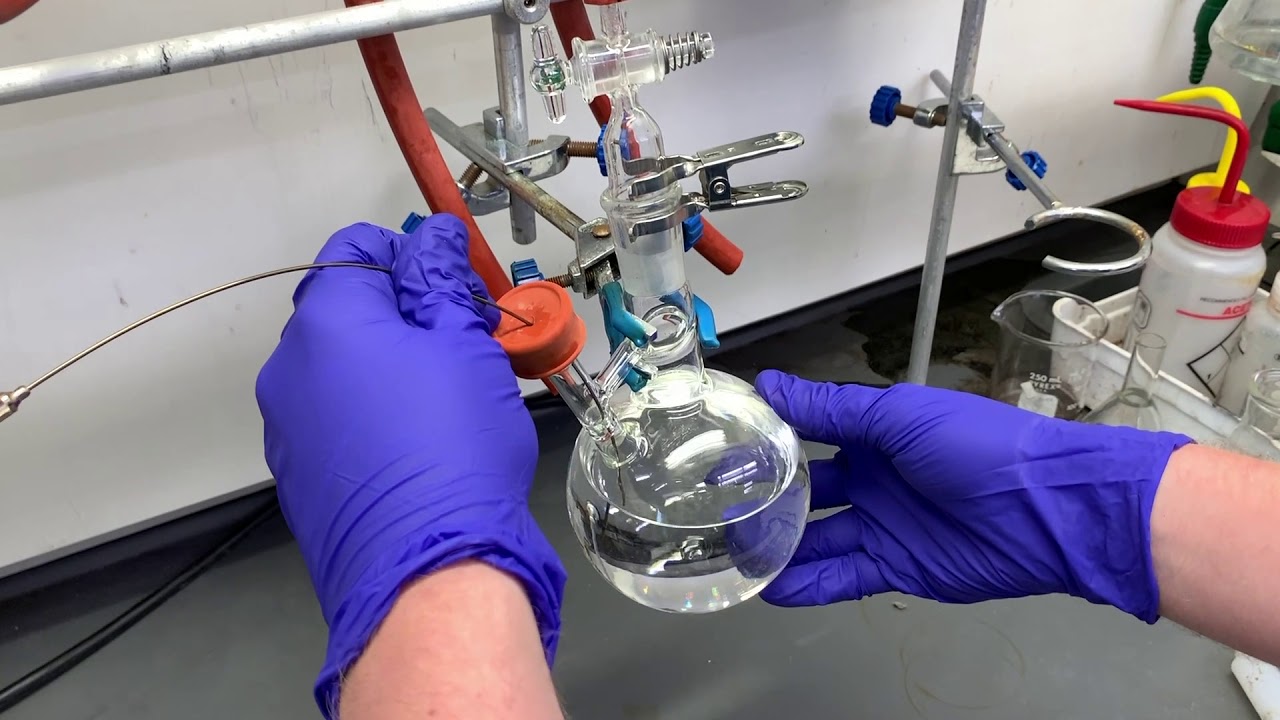

In chemistry, sparging, also known as gas flushing in metallurgy, is a technique in which a gas is bubbled through a liquid in order to remove other dissolved gas(es) and/or dissolved volatile liquid(s) from that liquid. It is a method of degassing.According to Henry's law, the concentration of each gas in a liquid is proportional to the partial pressure of that gas (in the gaseous state) in.

PPT Bioreaktor PowerPoint Presentation, free download ID2009930

Air sparging, also known as in situ air stripping and in situ volatilization is an in situ remediation technique, used for the treatment of saturated soils and groundwater contaminated by volatile organic compounds (VOCs) like petroleum hydrocarbons, a widespread problem for the ground water and soil health. Vapor extraction has become a very successful and practical method of VOC remediation.

Sparging a Solvent YouTube

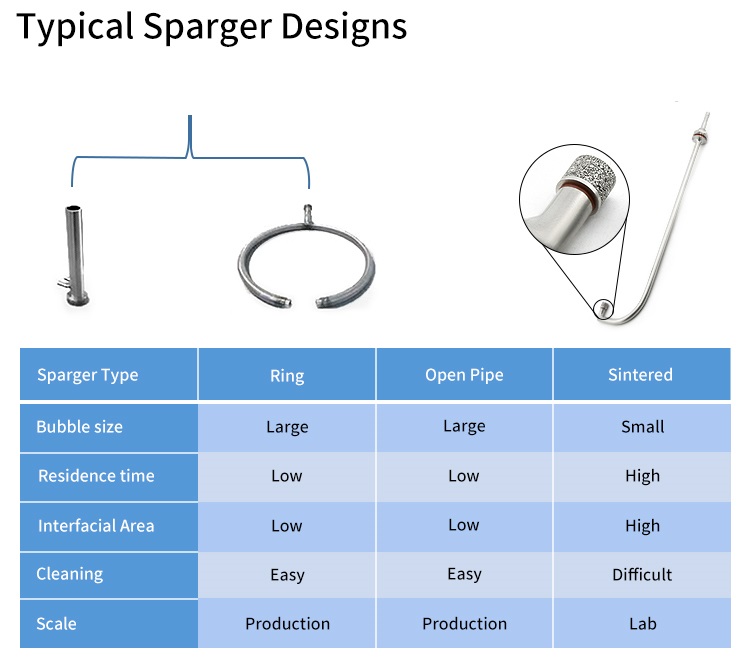

The effect of sparger design was investigated using three different sparger types. The first one is a simple pipe with an internal diameter equal to 5 mm, commonly known as Single Orifice Sparger - S-SO. The second one is a cone with a perforated base, the holes are arranged uniformly according to two criteria aiming to ensure a good bubble.

Sintered Sparger Sparger Systems Industrial Sparger Manufacturers

Industrial Sparger Systems. Mott sintered spargers, a key component in efficient gas-liquid contact systems, introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe and other sparging methods. The utilization of these spargers enhances the gas/liquid contact area.

What Is A Sparger In Bioreactor All You Want To Know Shenzhen, Guangdong Province, China

This work presents the influence of the sparger opening area, gas velocity, and bubble size on hydrodynamics and transition of the flow regime from uniform to re-circulatory in a rectangular bubble column using OpenFOAM. In the course of development of the model, the effect of several drag closures and lift on the predictability of the CFD model was studied by comparing the predictions with.

Low Profile 2Port Sparger 3L For Over Head Drive Vessels SKU196403415R Bellco Glass

A steam sparger is a type of direct contact heating device. Steam sparging is considered a traditional heating method, where the input temperature is much higher than the process temperature. Although steam injection is considered more efficient, steam spargers are also used in several industries. Some of the most important benefits of the.

Spargers for maximal contact surface between gas and liquid Teesing

The sparger orifice diameter and position has an effect on the bubble distributions and sizes in bubble column [30]. Sal et al. [15] investigated the effect of the orifice diameter of perforated plate spargers on gas holdup and regime transition in bubble column. Orifice diameter is found to have a significant effect on the total gas hold-up in.

What is Sparging when using brewery equipment TIANTAI® 1200hl Micro Beer Brewery Brewing

The use of a sparger in a fermenter offers several benefits: Improved Oxygen Transfer: The sparger ensures efficient oxygen transfer into the liquid, providing the necessary oxygen for the growth and metabolism of microorganisms or yeast. This is crucial for the success of fermentation processes. Enhanced Mixing: The introduction of gas through.

Bioreactor Sparger Manufacturer HENGKO

Sparger technology has developed significantly since the introduction of these first simple pipe systems. Although the first sparger design with automatic protection in case of air-supply failure was developed in the 1970s, this system suffered problems with wear. The concept of automatic closing was further developed in the 1990s.

Types Of Sparger In Fermenter Design Talk

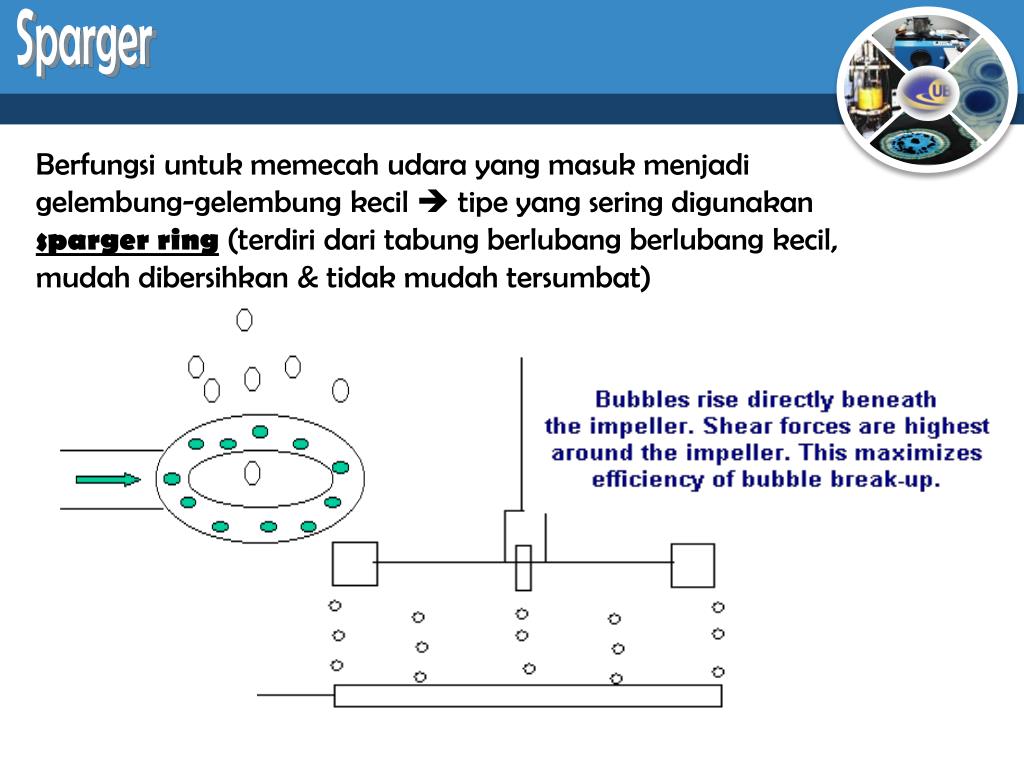

Sparger adalah aksesori penting untuk reaktor bubble column, karena sparger berfungsi untuk distribusi ukuran gelembung dan kenaikan kecepatan. Sparger terletak di bagian bawah reaktor dan berperan untuk memompa udara serta mencegah pembentukan gelembung oksigen (Meilany & Setiadi, 2008) Untuk mengurangi kadar CO 2