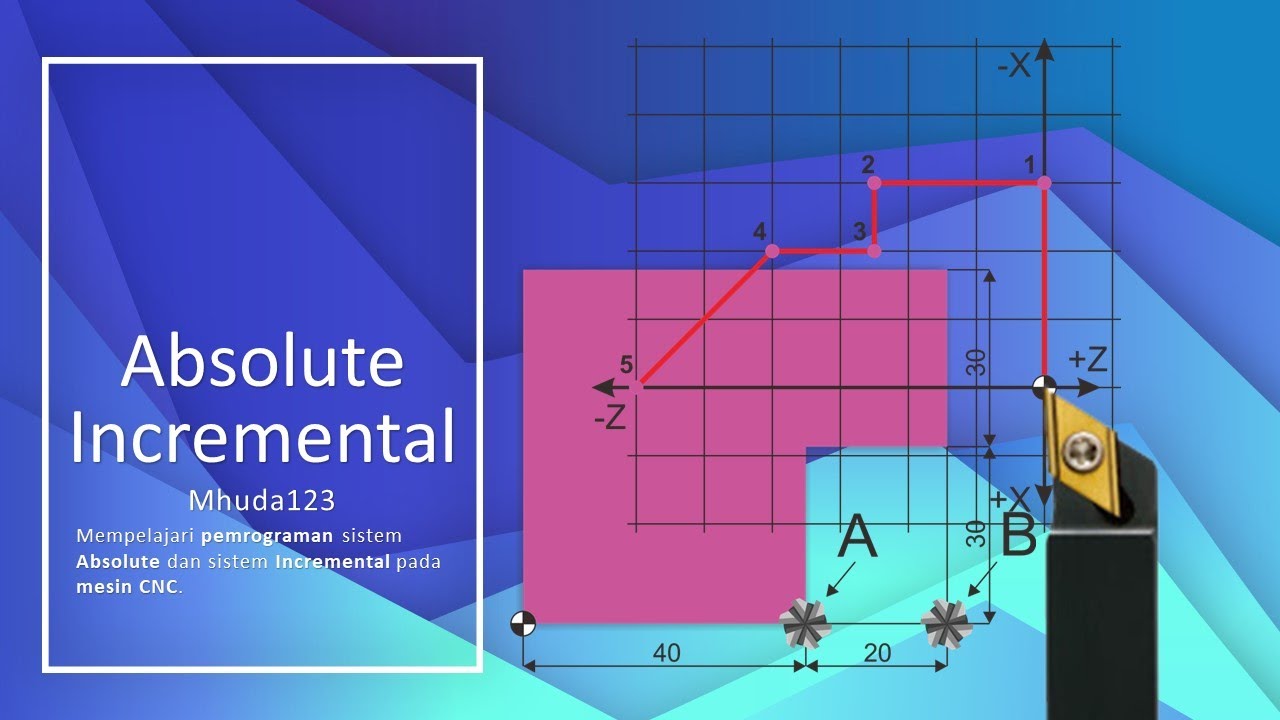

METODE PEMROGRAMAN ABSOLUTE DAN INCREMENTAL PADA CNC BUBUT ( CNC LATHE) YouTube

For manual programming, I find that a mix of the two worked the best. Absolute to locate the starting point of feature and incremental to follow the profile. Your machine could care less which system you use but this is what worked best for me. And yes, an incremental sub can be a powerful tool for effectively shortening a program.

CNC Lathe Programming Tutorial What is Absolute and Relative coordinate system Part 01 YouTube

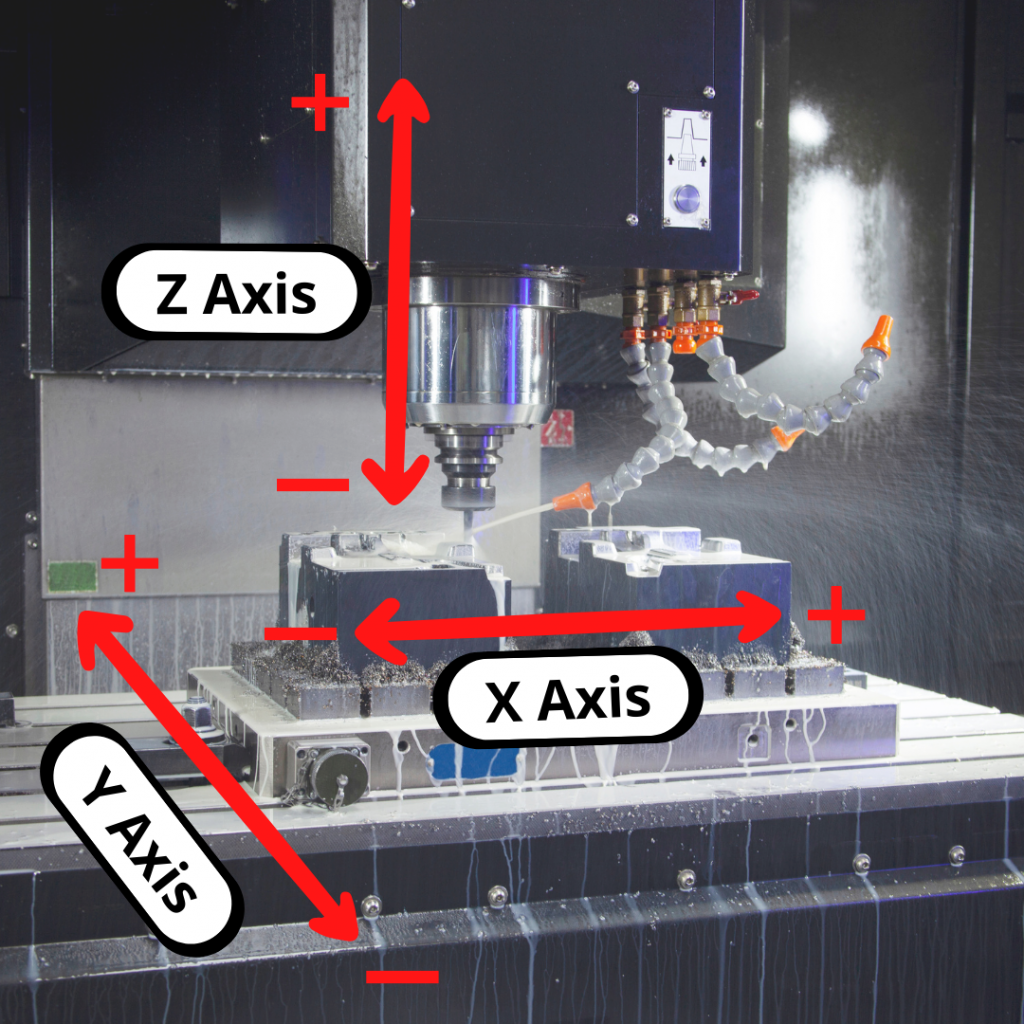

Absolute and Incremental Programming. It is possible to program based on absolute coordinates from programming zero (G90 Absolute) or to program from the coordinate where the cutter is located (G91 Incremental).. Assignment: Absolute coordinates. Create a CNC program for the drawing below. Programming is done in the 1st Quadrant and the.

Contoh Program Cnc Absolut Dan Incremental Terbaru

G91 [Incremental Positioning] While absolute positioning with G90 has a fixed origin or zero location, incremental positioning with G91 has a zero location that changes with each move. Every time the cutting tool moves to a new location, that location becomes the new zero point. Compare the picture below to the absolute positioning pic: The.

Contoh Program GCode Incremental Milling CNC Simulator Pro Bahasa Indonesia YouTube

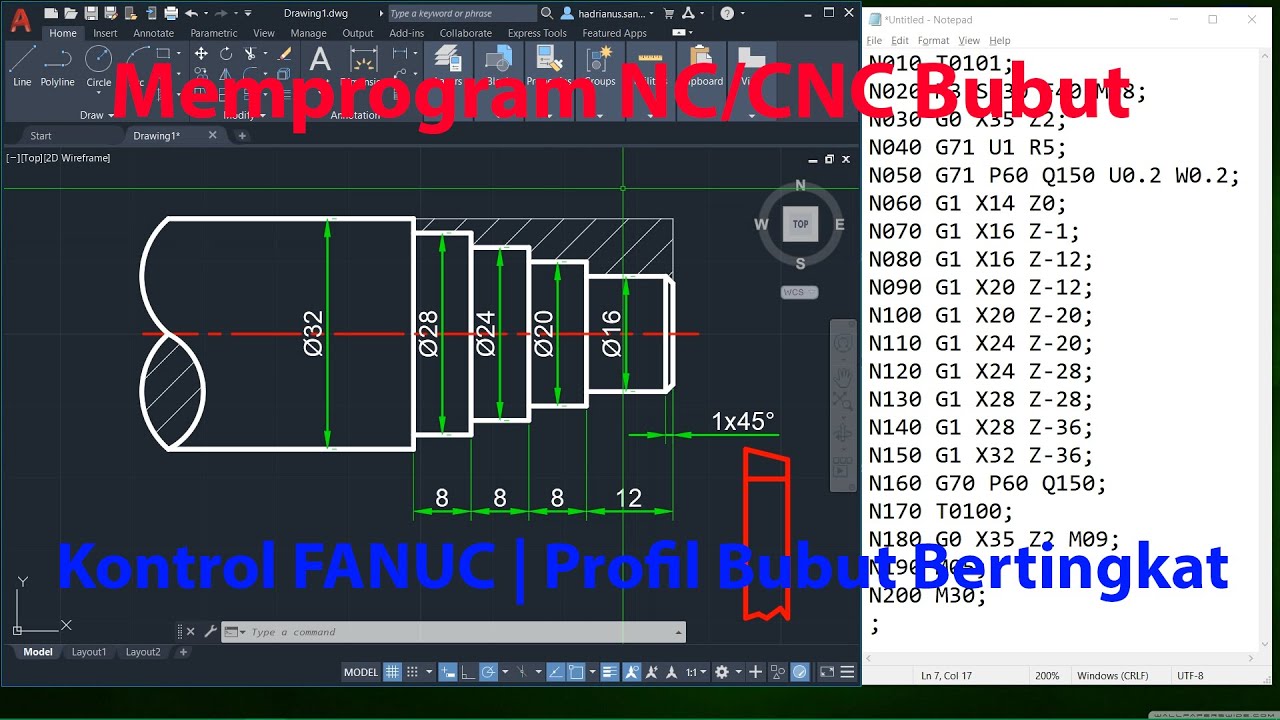

Perbedaan Program G-Code Milling dan Turning (Bubut) [ Panduan Lengkap] Pengertian Mesin Bubut dan CNC Dari Awal Sampai Akhir. Sekian penjelasan tentang Perbedaan Sistem Koordinat Absolute dan Sistem Koordinat Incremental pada G-Code CNC, semoga bermanfaat. Jika ada pertanyaan, silahkan sobat teknik-indo bisa tulis pertanyaan melalui kolom.

CNC Incremental dan Absolut YouTube

The BNT162b2 vaccine in 12-to-15-year-old recipients had a favorable safety profile, produced a greater immune response than in young adults, and was highly effective against Covid-19. (Funded by.

Contoh Program Cnc Absolut Dan Incremental Brain

When hand programming using a mix of absolute and incremental and looping code results in much smaller programs. Small programs are less likely to have typos than a large program. I started programming before CAM. Using incremental moves where advantageous was a great tool to reduce programming time.

ABSOLUTE & INCREMENTAL PROGRAMMING CNC MILLING. YouTube

In incremental programming, the G91 command indicates to the computer and MCU (Machine Control Unit) that programming is in incremental mode.Absolute Program. Absolute program locations are always given from a single fixed zero or origin point. The zero, or origin point may be a position on the machine table, such as the corner of the worktable, or at any specific point on the workpiece.

Mudah dan Simpel !!, Belajar Absolute dan Incremental pada CNC YouTube

Exercises. 1. Write a g-code program that feeds the cutter around a 1 inch by 1 inch rectangle whose center is at 1, 1. Use absolute coordinates (gcode G90). 2. Convert the program you wrote in #1 to use incremental coordinates (don't forget to include gcode G91!).

Incremental & absolute modes of CNC Programming YouTube

The video is the second part of CNC Programming Tutorial. CNC programming based on positioning system is explained here. Absolute and Incremental positioning.

Contoh Program Cnc Absolut Dan Incremental Terbaru

To be able to write and edit programs, you must know when and how to use Absolute and Incremental modes effectively. More programs are in absolute, but there are times when it's easier to use incremental.There are major differences between to the two, so if you don't know how each one works, don't start programming until you read this. Mixing the two up can and will cause a disas.

Contoh Program Cnc Absolut Dan Incremental Brain

INCREMENTAL COORDINATE PROGRAMMING (G91) OF THE MACHINING CENTER. In incremental systems, every measurement refers to a previously dimensioned position (point-to-point). Incremental dimensions are the distances between two adjacent points. The coordinate notations for the points on the drawing (in absolute and incremental systems) appear in the.

Contoh Program Cnc Absolut Dan Incremental Terbaru

In absolute mode, also known as G90, the tool coordinates are always referenced to a fixed point, usually the machine origin or a work offset. In incremental mode, also known as G91, the tool.

Contoh Program Cnc Absolut Dan Incremental Brain

We often use incremental programming to cut the same shape in 2 or more locations.The main program is used to locate with absolute and then we call-up the sub-program which incrementally cuts the shape. Dan, Good idea-does this actually reduce the jerkiness you get when the machine can't process the code fast enough?

Absolute and Incremental CNC Positioning Modes [G90 & G91]

There are two basic types of compensation available in today's controls: Absolute and Incremental. Incremental compensation is typically found in Japanese controls and Absolute compensation is found in most others. As the details of these types of compensation are investigated, it may be seen that there are advantages in each of the approaches.

CNC Programming using Absolute and Incremental Program / CNC Milling Program / CNC Program

Contact. Online Help. Absolute to Incremental Conversion. Use this option to convert selected part of CNC code to incremental (G91). You can select how to calculate first incremental move (from coordinates in a first selected block or from a zero) Click OK to change selected code. Note: CNC code is formatted according to currently selected.

Memprogram NC/CNC Bubut Profil Bubut Bertingkat + Simulasi YouTube

Absolute system. Most controls on machine tools capable of handling both by altering code between G90 (absolute) and G91 (incremental) commands. All considerations to this point accept that the absolute mode of programming is used. The CNC word used to refer to the absolute mode is G90. In absolute mode, the end points intended for all motions.