Hot Dip Galvanized Steel Strip NEWCORE GLOBAL PVT. LTD

SAFETY DATA SHEET FILE NO.: 4158 HOT-DIP GALVANIZED COATING SDS DATE: Rev 1, 01/01/2018 PAGE 3 OF 9 SECTION 4: FIRST AID MEASURES (cont'd) Short Term Effects: Ingestion: Ingestion of harmful amounts of this product as distributed is unlikely due to its solid insoluble form. Ingestion of dust may cause nausea or vomiting.

HOT DIP GALVANIS Fajar Indo Nusantara

We are a member of the Hot-dip Galvanizing Association of Indonesia: AGI - Asossiasi Galvanis Indonesia. There has been a 3-shift operation of two galvanizing lines here since 2019. Kettle dimensions: 10.0 x 1.5 x 3.0 m as well as 13.0 x 2.0 x 3.4 m Color Coating: Constructions up to 30 m x 7 m, Maximum weight 8 mt

A992 A572 Hot Dip Galvanized Steel Strip With Thickness 0.15mm 2.5mm

It is also not to be used for steel less than 22 gage thick. The ASTM A123-17 document details specifications for materials, including the steel or iron, zinc, and bath composition, and coating properties, such as the coating thickness, finish, and appearance. In addition, it addresses sampling and test methods to assure that the zinc coating.

Hot Dip Galvanize High Tensile Strenght Bolt and Nut Pitoe Karya

Hot-dipped galvanization involves submerging the steel in molten zinc, whereas galvanized steel is coated with a protective layer of zinc through electroplating. The main difference is in how they are applied; hot-dipped coating offers a stronger, thicker layer that works especially well in abrasive situations.

Maju Jaya Galvanis Pusat Hot Dip Galvanis

Hot Dip Galvanis. Hot Dip Galvanizing merupakan proses perlindungan besi dengan sistem pengorbanan anoda berupa Zinc melalui proses elektrokimia. Hot Dip Galvanizing dilakukan dengan cara mencelupkan atau membenamkan bahan besi dalam bentuk apapun ke dalam tungku panas yang telah berisi cairan Zinc dan dilakukan setelah bahan besi tersebut.

Hot Dip Galvanizing Dipping Process....... in action YouTube

Hot Dip Galvanis adalah suatu metode pelapisan (Coating) melalui proses pencelupan kedalam cairan atau lelehan seng (Zn) dengan tujuan untuk meningkatkan ketahanan terhadap korosi. Komponen Baut yang digunakan berbahan baja karbon rendah (Low Carbon Steel) A325. Temperatur yang digunakan pada proses Hot Dip Galvanis adalah 450°C dengan waktu.

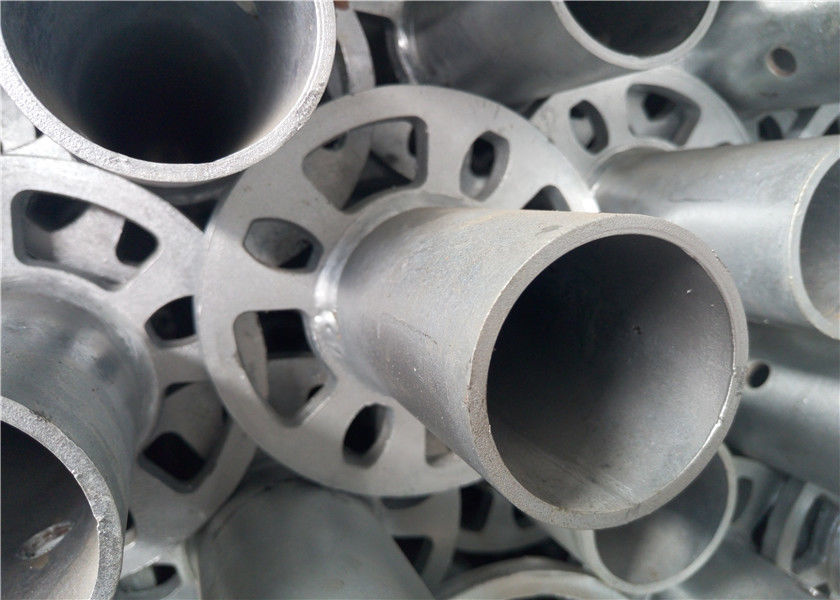

Sistem Hot Dip Galvanis Ringlock Scaffolding Gravity SelfLocking

Hot-dip galvanizing provides a number of benefits to the steel it protects. The metallurgically-bonded zinc-iron alloy layers not only create a barrier between the steel and the environment, but also cathodically protect the steel. The cathodic protection offered by zinc means the galvanized coating sacrifices itself to protect the underlying.

HotDip Galvanizing at Rs 25/kilogram हॉट डिप गैलवनाइजिंग galvanizing service M.S

Repairing HDG Steel. The touch-up and repair of hot-dip galvanized steel coatings is important to maintain uniform barrier and cathodic protection as well as ensure longevity. Although the hot-dip galvanized coating is very resistant to damage, small voids or defects in the coating can occur during the galvanizing process or due to improper.

Proses Hot Dip Galvanis

in order to provide excellent service to customer and best quality Hot Dip Galvanizing Services, Bondi Galvanizing is consistently applying quality management system ISO 9001:2015, following the Hot Dip Galvanizing production standard of SNI 07-70330-2004 from Indonesia Industrial Department and Strictly in Accordance with ASTM A-123.

Tiang Galvanis Hot Dip 10 30M ASTM 123 ASTM 153 30FT 10KV 550KV

Established in 1993, PT.Lazuardi Rukun Perkasa is one of the leading providers of Hot-dip Galvanizing services for iron steel (besi baja) in Indonesia committed to providing top-notch service for our customers. A family-owned business, we service a wide range of clients from small fabricators to major multi-national corporations from our 2 major plants that located within the same industrial.

Hot Dip Galvanized Steel Pipe Produsen dan Pemasok Cina Pabrik Profesional WANLEI

PT Bumi Agung Perkasa Indah (BAPI) merupakan perusahaan yang bergerak dalam bidang industri Hot-Dip Galvanizing di Indonesia sejak tahun 1983. PT Bumi Agung Perkasa Indah (BAPI) telah tersertifikasi ISO 9001: 2008 oleh Sucofindo. PT Bumi Agung Perkasa Indah berkomitmen memberikan pelayanan yang terbaik bagi setiap pelanggan dari segi kualitas.

Produsen Galvanisasi Hot Dip Kustom Fabmann

The purpose of hot-dip galvanizing is to protect the material from corrosion by creating a layer of zinc that acts as a protective coating. The process of hot dipping is to submerge the metal into a bath of molten zinc, which metallurgically bonds itself to the material (usually steel). This then protects the material against external elements.

Jasa Hot Dip Galvanized / Galvanizing Surabaya oleh PT. Catur Jaya Anugerah

Baut Mur Hot Dip Galvanis / Hot Dip Galvanized. Product Code: 11111. Availability: In Stock. Rp 0. Qty. Add To Inquiry. Add to Wish List. Compare this Product. Description.

PROYEK HOT DIP GALVANIS DAN INVESTASI HOT DIP GALVANIZE

Baca Juga: Definisi Galvanis, Keuntungan Dan Proses Galvanisasi. Proses Hot Dip Galvanizing. Agar lebih memahami tentang metode hot dip galvanizing, kita bisa melihat proses pelapisannya mulai dari pembersihan hingga finishing. Setidaknya, terdapat tiga langkah dasar dalam proses hot dip galvanizing, yaitu persiapan permukaan, galvanisasi, dan.

Hot Dip 2 Inch Jadwal 80 Pipa, Hot Rolled Round Tube Besi Galvanis

Solusi untuk anda yang membutuhkan Jasa Pencelupan Hot Dip Galvanis untuk melindungi besi dan baja terhadap korosi. PT. TANGGUH ADI PERKASA TAP siap melayani kebutuhan anda. Pentingnya Galvanis . Galvanis merupakan material seng dengan tingkat konsentrasi kemurnian tinggi yaitu 99,7%. Material ini digunakan untuk melapisi besi, baja ringan dan.

HOT DIP GALVANIS Fajar Indo Nusantara

Galvanization. Galvanized surface with visible spangle. Galvanization or galvanizing ( also spelled galvanisation or galvanising) [1] is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanizing, in which the parts are coated by submerging them in a bath of hot, molten.