Brand Hydraulics SidePorted Adjustable Flow Control Valve — 3/4in. NPT

Flow control is the act of controlling the order in which actions and subflows run. Power Automate enables you to implement flow control through the flow control actions. Labels are used to create points of reference for the Go to action that changes the running point of the desktop flow. The following example directs the flow to a label.

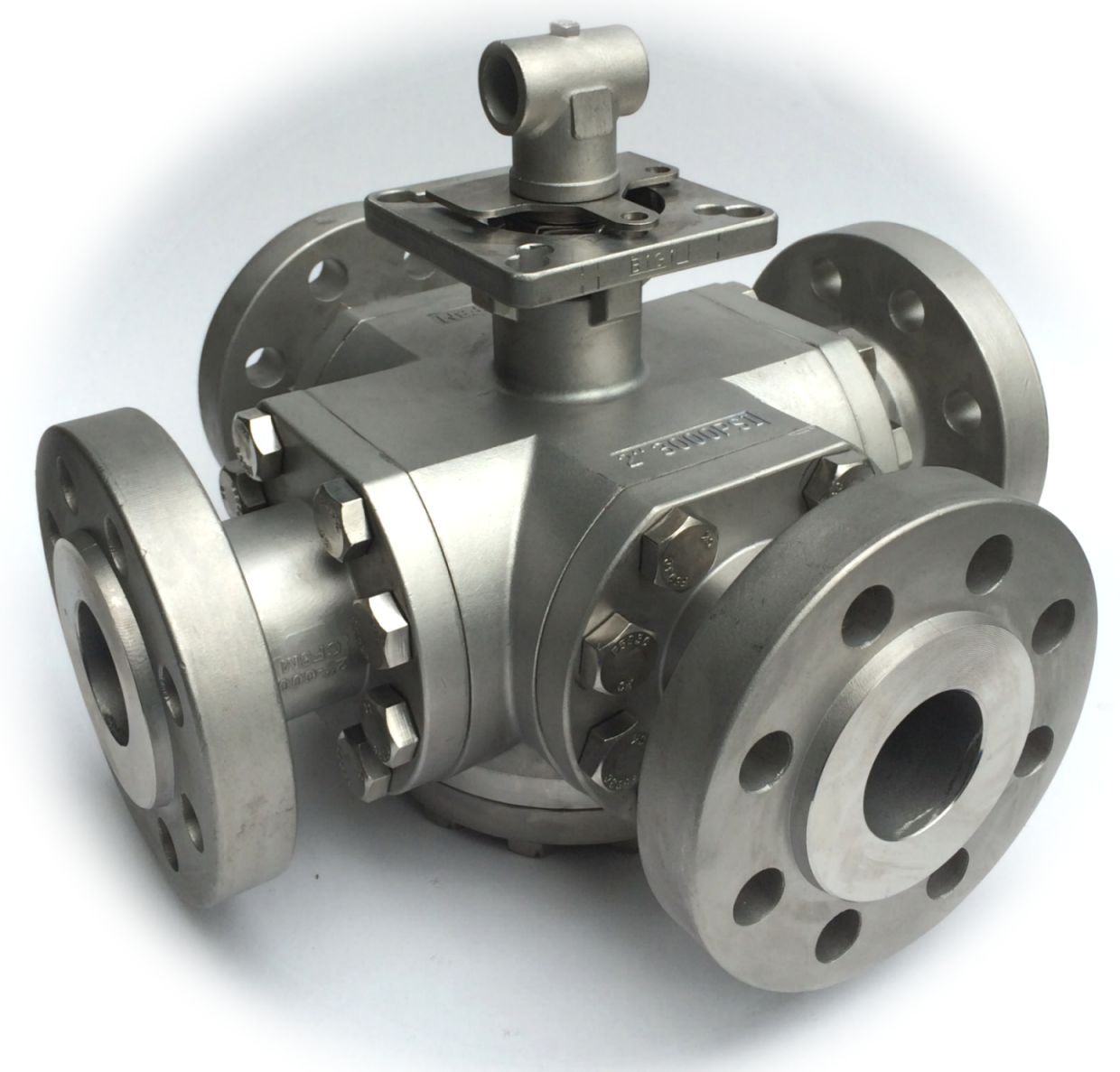

J Flow Controls Series DMHP3(4)L(T)2A00 High Performance Flanged Multi

A control valve is a device that is used to control the flow of liquids or gases. It is commonly used in industries such as: oil and gas, chemical processing, and manufacturing. These valves operate automatically or manually and come in various types, including the most commonly used types: the globe, butterfly, and ball valves.

Products Flow Control Valves

Ethernet flow control is a mechanism for temporarily stopping the transmission of data on Ethernet family computer networks. The goal of this mechanism is to avoid packet loss in the presence of network congestion. The first flow control mechanism, the pause frame, was defined by the IEEE 802.3x standard.

Proportional ElectroHydraulic Flow Control (and Check) Valves

Flow control is a critical aspect of technology, particularly in data communication and networking, where it manages the rate of data transmission between two nodes to ensure that a fast sender cannot overwhelm a slow receiver. Without effective flow control, data packets could be sent at a rate that exceeds the recipient's processing.

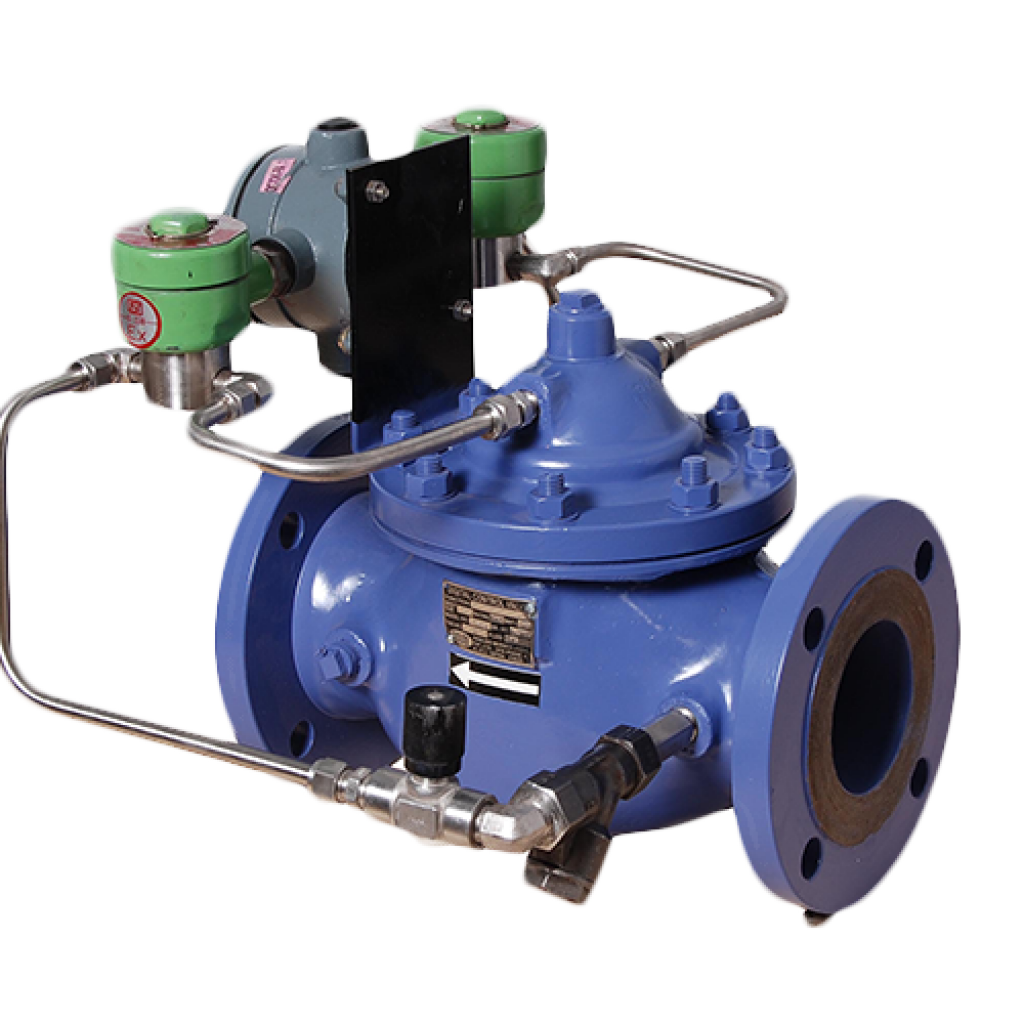

Flow Control Valves ClaVal

Flow control (data) In data communications, flow control is the process of managing the rate of data transmission between two nodes to prevent a fast sender from overwhelming a slow receiver. Flow control should be distinguished from congestion control, which is used for controlling the flow of data when congestion has actually occurred. [1]

Double Acting Inline Flow Control Valves Berendsen Fluid Power

Flow Control. Flow control tells the sender how much data should be sent to the receiver so that it is not lost. This mechanism makes the sender wait for an acknowledgment before sending the next data. There are two ways to control the flow of data: Stop and Wait Protocol. Sliding Window Protocol.

Flow Control Valves Needle, Manifold, Metering and Gate Valves

Summary. A general introduction to flow control is presented, including the background, classification, and features of various passive and active techniques. The passive methods include Gurney flap, vortex generator, bump, cavity, roughness, small disturbance, bleed, splitter plate, polymer, and biomimetic techniques.

Buy H2 Flow Controls FVC Control FlowVis 2 x 2.5in. Complete Pool Flow

Demand-Compensated Flow Controls Flow controls can also bypass excess system flow to a secondary circuit using demand-compensated flow control valves as shown in Figure 4 below. Fluid is routed at a controlled flow rate to the primary circuit, and bypass fluid can be used for work functions in secondary circuits without affecting the primary one.

SVF Flow Controls, Inc. FlowRATE Newsletter August 2017

The flow control sector, which is part of the broader industrials sector, consists of companies that provide products or services involving the management and control of liquids and gases. Such products include pumps, valves, compressors, meters, filtration products, and other related equipment. These are some of the most critical and prevalent components in modern industries.

3M Air Flow Control Valve 12T02316573 Grainger

About Us Flow Control Group companies are strategically positioned throughout North America's largest industrial hubs. Our family of companies in the US and Canada act as a critical intermediary between suppliers and customers offering products and technical services that are essential in the movement of mission critical components to a diverse array of end markets and applications.

5 Signs Your Flow Control Equipment Needs An Upgrade? Flowmetrics

Flow control at the Data Link Layer essentially limits and coordinates the number of frames or quantity of data that a transmitter can send before waiting for an acknowledgement from the receiver. It is a series of procedures instructing the transmitter on how much data or frames it can move or broadcast before data overloads the receiver.

Flow Control Valves Continental Hydraulics

Flow control is a very common objective in fluid power systems. Usually, controlling the force, velocity, position, etc. of hydraulic actuator is achieved by adjusting the flow rate of the hydraulic fluid. There are various techniques in which flow can be controlled. Choosing the appropriate flow control method depends on several factors including the systems requirements, the available space.

Single Acting Inline Flow Control Valves with Reverse Free Flow

Flow control is a technique that allows two stations working at different speeds to communicate with each other. It is a set of measures taken to regulate the amount of data that a sender sends so that a fast sender does not overwhelm a slow receiver. In data link layer, flow control restricts the number of frames the sender can send before it.

WATTS Rate of Flow Control Valve Valmatic

What is flow control? Flow control is a technique used to regulate data transfer between computers or other nodes in a network. Flow control ensures that the transmitting device does not send more data to the receiving device than it can handle. If a device receives more data than it can process or store in memory at any given time, the data is.

Brand Hydraulics Electronically Adjustable Flow Control Valve 055

Flow control is design issue at Data Link Layer. It is a technique that generally observes the proper flow of data from sender to receiver. It is very essential because it is possible for sender to transmit data or information at very fast rate and hence receiver can receive this information and process it. This can happen only if receiver has.

Hydraulic Flow Control Valve w/ Free Reverse Flow, 1/8" NPT Ports

Parker flow control valves are designed to regulate the flow rate and pressure of media through a pipeline. Flow control valves are essential for optimising system performance and relying on a flow passage or port with a variable flow area. The range includes pneumatic and hydraulic control valves which are designed to cope with high flow rate working pressure and can be used for a variety of.