Hot runner manifold EMP E.M.P. srl

This manual gives guidance on basic gate design and hot runner selection for the robust molding of semi-crystalline resins. 2.1.2. Hot Runners with Valve Gates (Shut-off Nozzles) 4. 3 Hot Runner Manifold. 4 Temperature distribution inside the Hot Runner. 5 Temperature control of the cavity.

Hot runner manifold Eastern Plastics Injection Moulding and Hot Runner Solutions

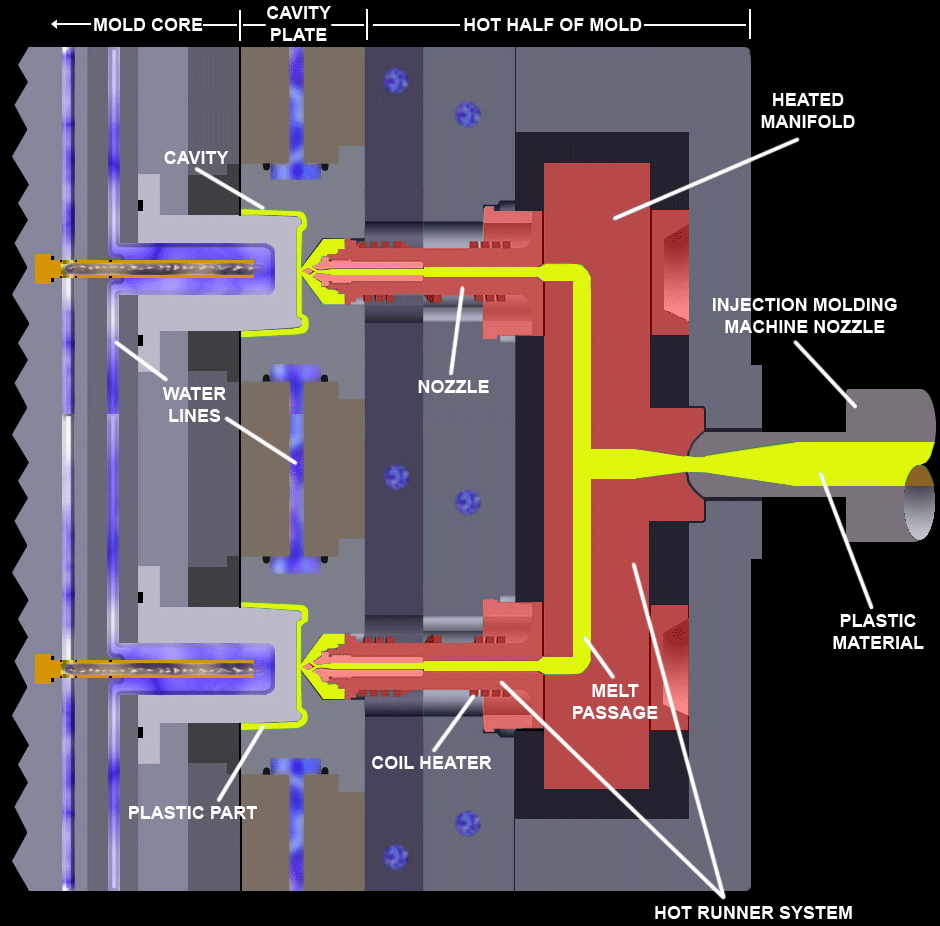

How Hot Runner System Works. The hot runner molds are made up of two plates that are heated with a manifold system. The function of the manifold is to maintain a consistent temperature. This is done by keeping the molten thermoplastic in the runners at the same temperature as the temperature of the heating cylinder.

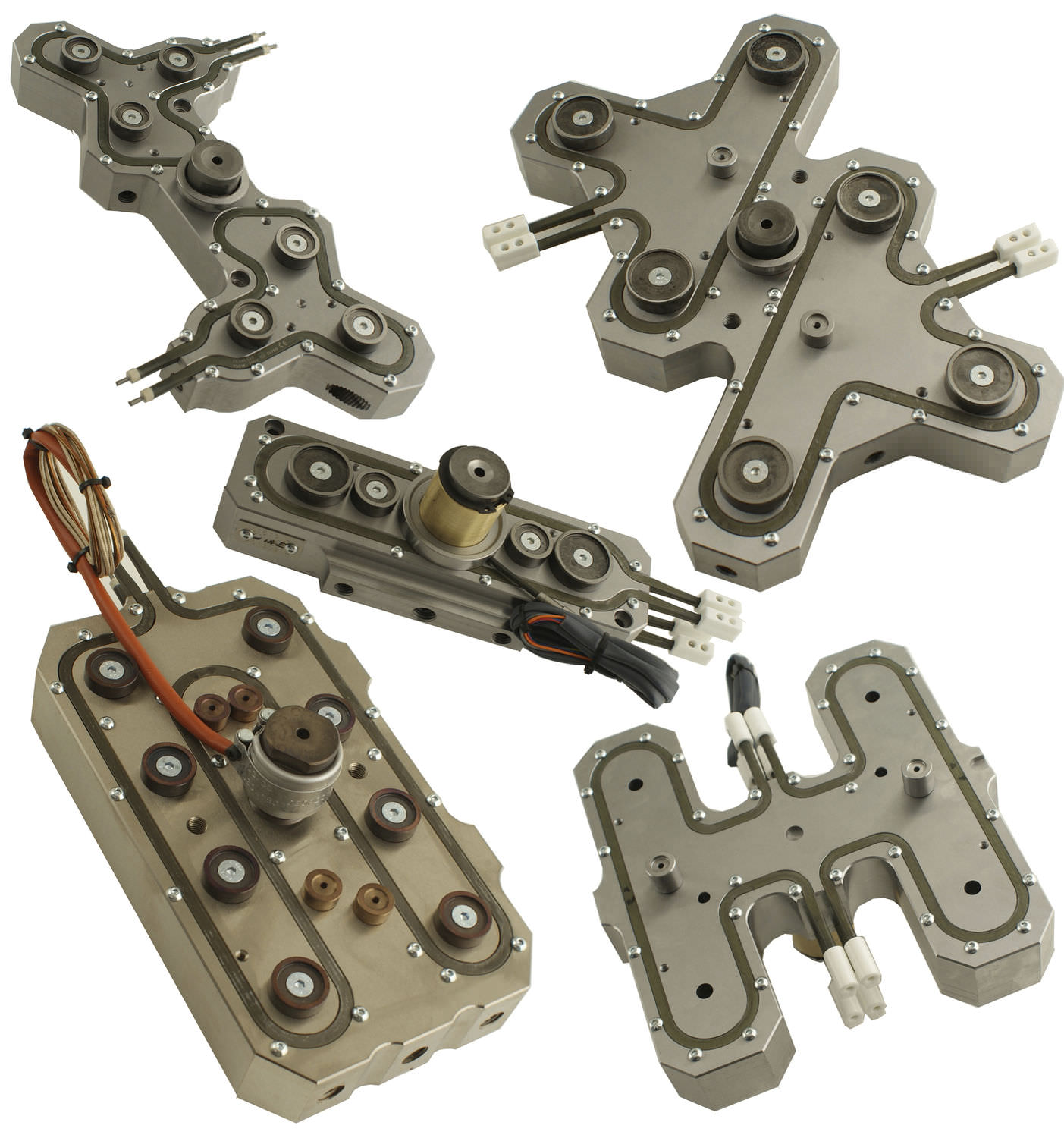

PolyFlow Hot Runner System Pre Wired Hot Runner Systems

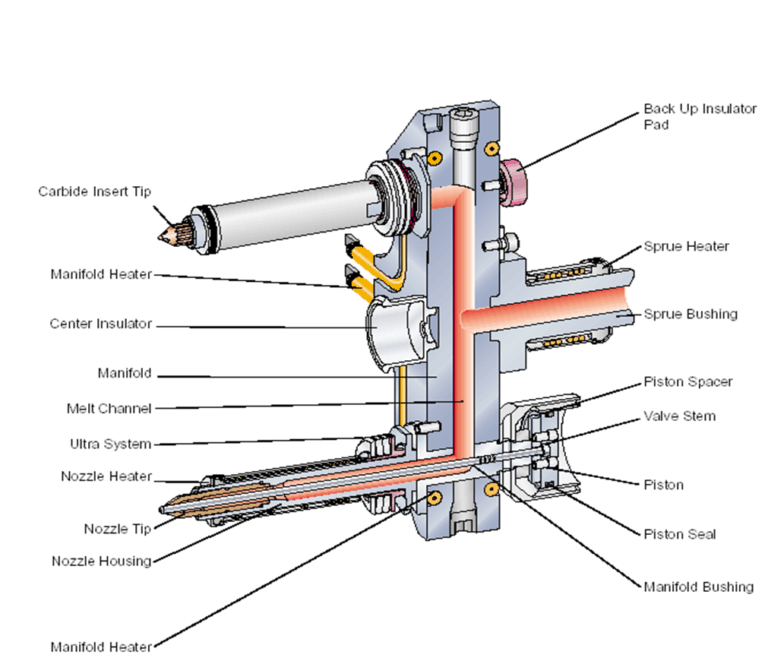

The hot runner system consists of a manifold, which is a heated block with multiple channels, and a series of nozzles that deliver the molten plastic directly into the mold cavities. The channels and nozzles in the hot runner system are heated to maintain the plastic in a molten state throughout the injection molding process.

hot runner design

Depending on the type of resin and the design of the hot runner the inlet component may be heated in order to optimize the molding process. Manifold - The manifold enables the flow of resin into different nozzles and injection points (gates). Manifolds are normally used where multiple cavities are injected or where more than one nozzle/gate.

Hottechs Hot Runner

That will prevent heater shorts and promote heater life.Keep barrel nozzle temperature below melt temperature. The barrel nozzle temperature should be set 25 deg F below the melt temperature, which then becomes the starting point for the manifold temperatures. Hot runner temperatures typically ramp downward from the runner bushing to the tip.

Hot runner Sositar

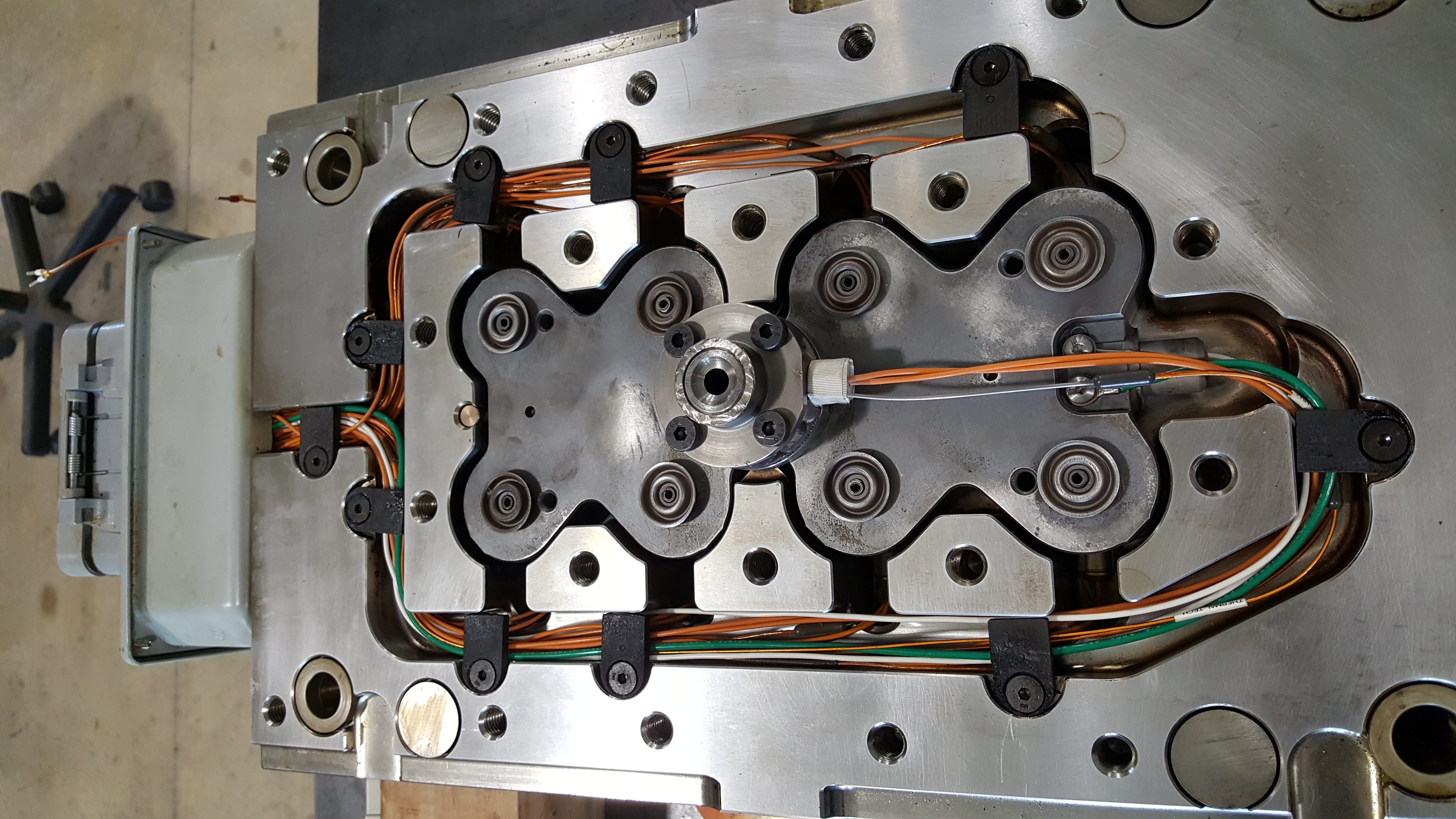

Manifold plate design. The manifold plate of the hot runner has three primary operations to perform. The first one is to provide support to other components. The second is to offer a surface area for backing plate bolts. At last, the manifold plate also works as backup support for the cavity plate.

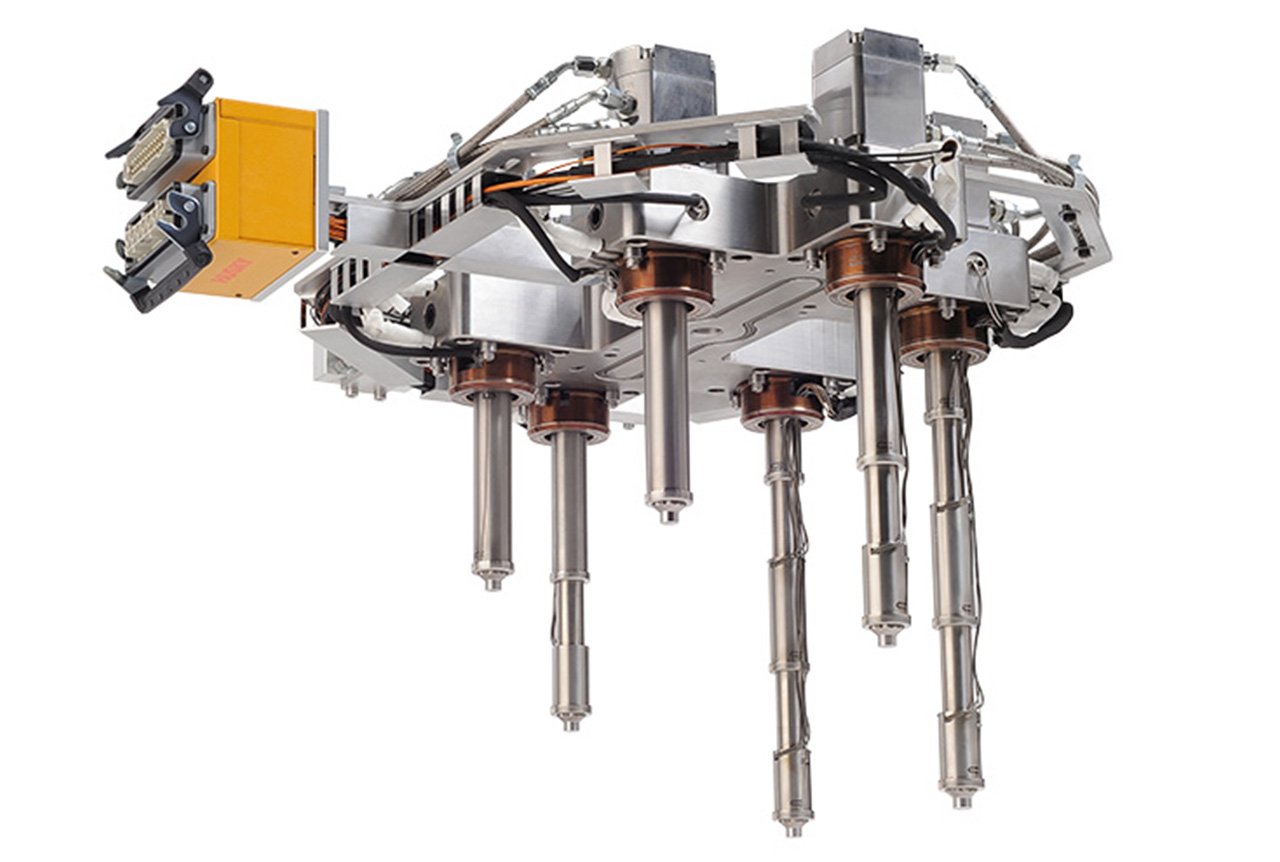

Hot Runners Husky Technologies

2 OPEN HOT RUNNER SYSTEMS Manifold systems Different manifold versions can be selected for different applications, from partially or fully balanced to customer-specific special solu-tions. Flexible positioning of hot runner nozzles with a manifold make individualised mould design possible. We reserve the right to make technical changes. 07/18

Hot Runner Replacement Parts and Products Polyshot

A hot runner mold system is a two-plate injection molding assembly that uses a runnerless heated manifold system and heated nozzles, managed by a temperature control system, to keep the thermoplastic in a molten state until it is finally injected into the cavities through temperature-controlled gates (drops) to form the final part where it is then cooled and ejected from the mold.

Hot Runner Tooling Injection Molding LHR Technical Service

How Hot Runner Manifold Design Influences Color Change. Another influence to color change with hot runners is the manifold design. This applies to any hot runner, regardless of nozzle or gating style. Manifold melt volume and shot count is a necessity for any hot runner application, with some manifolds containing more melt than others. That.

Multicavity hot runner manifold block with two layers runner

1.Layout and Design Hot Runner Guide. 1 / 20 C P T A. Hot runner nozzles b) Hot runner manifolds c) Melt flow control technology d) Connections e) Hot halves Nozzle ranges with flow bores from 3.5 to 25 mm, as single or manifold nozzles, make it possible to implement a very wide range of

Hot Runner System Types And Their Application In Plastic Injection Mold My XXX Hot Girl

Hot runner manifold design optimizes the distribution of molten plastic, reducing waste and improving product quality. Water manifolds maintain mold temperatures, enhancing consistency and efficiency in the molding process. Together, these components are essential for efficient and high-quality plastic part production.

Hot Runner Manifold Block Suppliers & Manufacturers in India

Manifold requirements also play an important role in initial system design implementation. Hot runner manifolds are available in an unlimited number of custom sizes with flexible drop locations. Manifold shapes and sizes are dependent on the number of mold cavities and spacing. Channel layouts must be balanced to achieve optimal flow conditions.

Hottechs Hot Runner

Plates Hot Half System Mould Design Recommendations 1.0 Plate Requirements Manifold and Back Plate Material • High strength material must be used for the plates. • Minimum plate material is 1.2311/1.2312, 30HRC, 800MPa Yield Strength. Manifold and Back Plate Thickness

Hot Runner System Hot Runner Manifold 4 Drop Manufacturer from Mumbai

Design flexibility and customized solutions Hot runner components. Nozzles are the hot runner components designed to inject the plastic melt into the cavities. There are three main types of injection:. The main task of the hot runner manifold is to distribute the plastic material into different nozzles.

mold hot runner manifold manufactures I type balance designWMFI0001

General Hot Runner Information Hot Runner Product Handbook v 19.4 Cooling Recommendation - HT Style Section-View Details HT Cap TS HT-S6 Sidegate COOLING SLOT OR CHANNEL: MIN FLOW RATE 5 L/MINUTE A B 1-1.5 ∅ 2-3 ∅ A B 1-1.5 ∅ 2-3 ∅ A B 1-1.5 ∅ 2-3 ∅ A Note 1-1.5 ∅ Position the cooling center- line at the mid point of the seal.

Threepiece hot runner manifolds prove popular in packaging applicatio

Note the encapsulated manifold heater design in this rear view of a 32-cavity hot half. Although this feature seems complex, its use is justified because of its much extended heater life and superior temperature uniformity.. While the main objective is always system performance, the hot runner design should also help reduce the probability.