Plating Thickness Gaugecoating thickness measurement

Measuring coating thickness enables you to reduce material costs, meet important industry norms, and safeguard the reputation of your business. This holds true regardless whether it is during production or inspecting incoming goods. Whether you are painting or electroplating, applying materials to magnetic or non-magnetic substrates, Fischer.

Plating Thickness Gaugecoating thickness measurement

Analyze electroplated coatings such as chrome/chromium (Cr), copper (Cu), nickel (Ni), tin (Sn), gold (Au), titanium (Ti), silver (Ag) and zinc (Zn) on a wide range of substrates including metals, plastic (plating on plastic: POP), ceramic and glass.

Plating Thickness Tester Plating Thickness Meter Plating Thickness

Measuring the thickness of electroplated coatings is an important task in the manufacturing process. It is necessary to know the thickness of the coating in order to determine the quality and uniformity of the final product. There are several methods that can be used to measure the thickness of coatings on electroplated surfaces.

Coating Thickness Gauges Fischer Technology Separate Probe

An eddy current thickness gauge measures the thickness of non-conductive coatings on non-magnetic substrates such as copper, aluminum, and brass. ECT gauges detect common coating defects, including corrosion, cracking, erosion, thickness loss, and material degradation. ECT gauges have multiple benefits, including:

Plating Thickness Tester, Plating Thickness Meter, Plating Thickness Gauge

ISSN: 0003-5599 Article publication date: 1 July 1954 Permissions Downloads 71 Abstract There are a number of reasons for applying metallic or non‐metallic coatings to metal articles, the most common being to prevent the atmosphere coming into contact with the base metal and setting up corrosion.

Electroplating Thickness Gauge Meter for Manufacturing Industry Metal

X-ray fluorescence (XRF) analysis is a fast and non-destructive method for measuring coating thickness and composition of plating deposits of a broad range of materials with high accuracy. One major advantage of XRF analysis is that thickness and composition of both single and multiple coatings can be measured simultaneously.

anodizing thickness testercoating thickness measurement

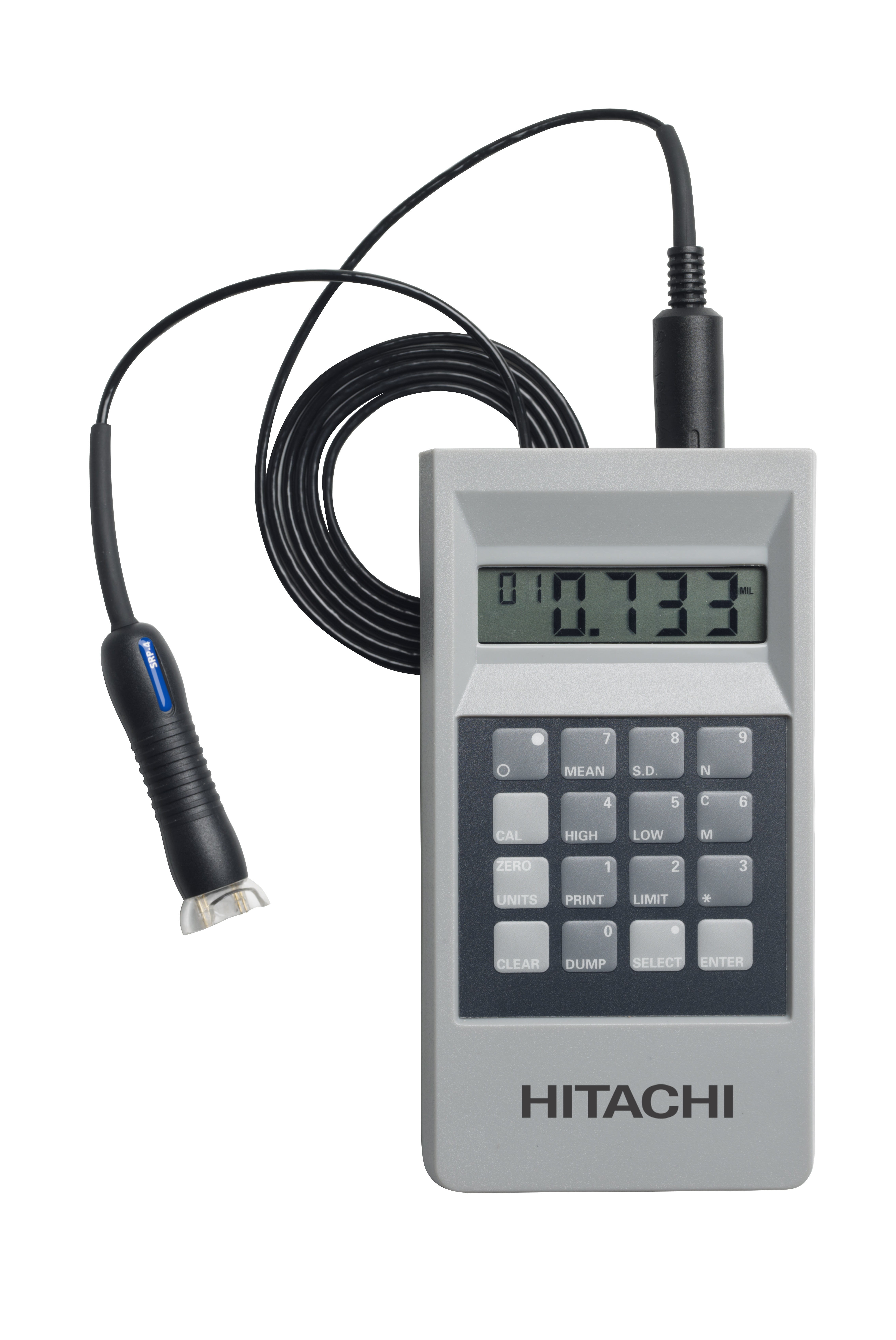

Plating thickness gauges are specialized instruments designed to measure the thickness of electroplated coatings accurately. They play a pivotal role in quality control during the electroplating process.

Plating Thickness Tester Plating Thickness Meter Plating Thickness

SGS MSi can perform plating thickness using SEM and Optical Microscopy (Image Analysis) on material as thin as .25 microns (.000010 in. or 10 micro-inches). Each examination is traceable to NIST Standard 484. Samples are prepared, mounted and examined using the specified method.

Electroplating and Metal Coating Thickness Gauges Quote, RFQ, Price

Coating thicknesses are typically found in the range from 0.1 to 85+ microns, depending on the application, and it is imperative that the thickness of coatings are monitored and controlled. Proper coating thickness is required to ensure consistent part performance and appearance. Why plating thickness is important

Plating Thickness Tester Plating Thickness Meter Plating Thickness

As a clear example, lets use a gold plated watch case to illustrate a point. Luxury quality watch cases from some manufacturers have been plated in gold (18 kt color) up to 20 microns (1/50 of a millimeter) in thickness. This by far exceeds the 2.5 microns required for "heavy gold plate" under F.T.C. rules.

ET 2 electrolytic thickness measuring instrument coating film thickness

The thickness of electroplating usually ranges from 0.0001 inch to 0.020 inch. While these may seem like small measurements, even the slightest build-up of thickness can provide great durability and corrosion resistance. Electroplating Thickness Control

Plating Thickness Gauge How To Measure Plating Thickness?

The unit functions when electrons or beta particles penetrate the surface of a plated part and interact with the gold layer and are counted as "backscattered" to a detector or Geiger-Muller tube. For accurate readings, the density difference must be at least 20% between the plated layer and the substrate. X-Ray Fluorescense

Chrome plating thickness measurement KIMI S.A.

The anodic dissolution method, also known as Faraday's Coulometric method, works on the lines of the electroplating process: electric current passed through an electrolyte separates individual metal coatings from the substrate. By measuring the current and time the Galvano Test determines the thickness of the coating separated.

Plating Thickness Gaugecoating thickness measurement

For most plating applications, the most common methods of measuring plating thickness are X-Ray Fluorescence (XRF), Optical Emission Spectroscopy (OES), and Eddy Current Testing (ECT). XRF is a highly accurate technique that can measure the thickness of a plated layer up to 10 mm thick.

Plating Thickness Tester Plating Thickness Meter Plating Thickness

A Minimum thickness requirement is defined as all readings measured on the significant surfaces must be greater than the thickness indicated. In the example provided the thickness measured on any significant surface would have to be greater than 0.0002" (200uin).

China Electrolytic Thickness Gauge for Electroplating Process of Metal

In the electroplating industry, thickness is measured on the scale of microinches. One microinch [µin] is equivalent to 1 millionth of an inch. In mathematical terms, it would be defined as .000001″. To measure the thickness of the deposit, an X-ray fluorescence (XRF) is typically used.