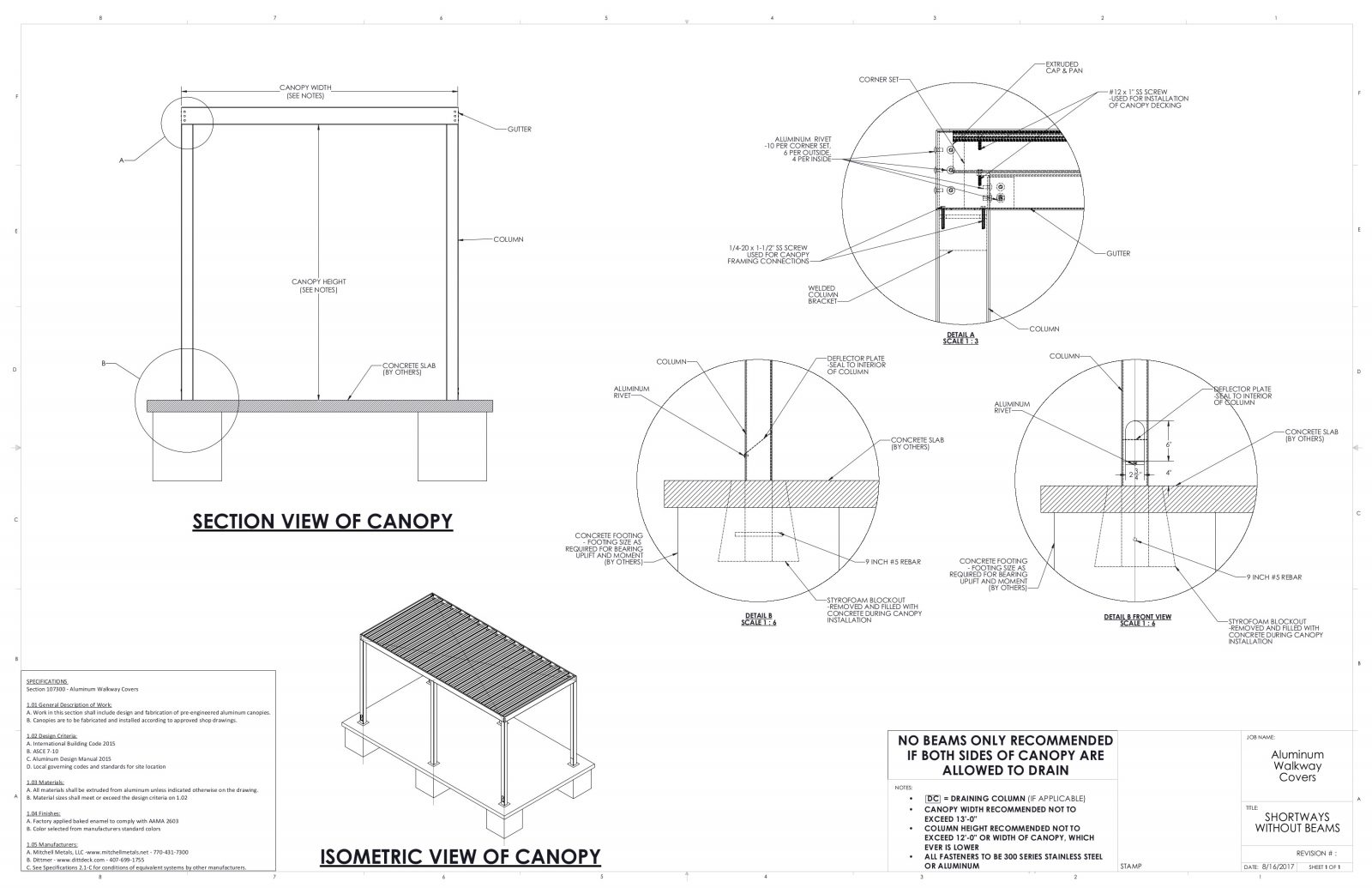

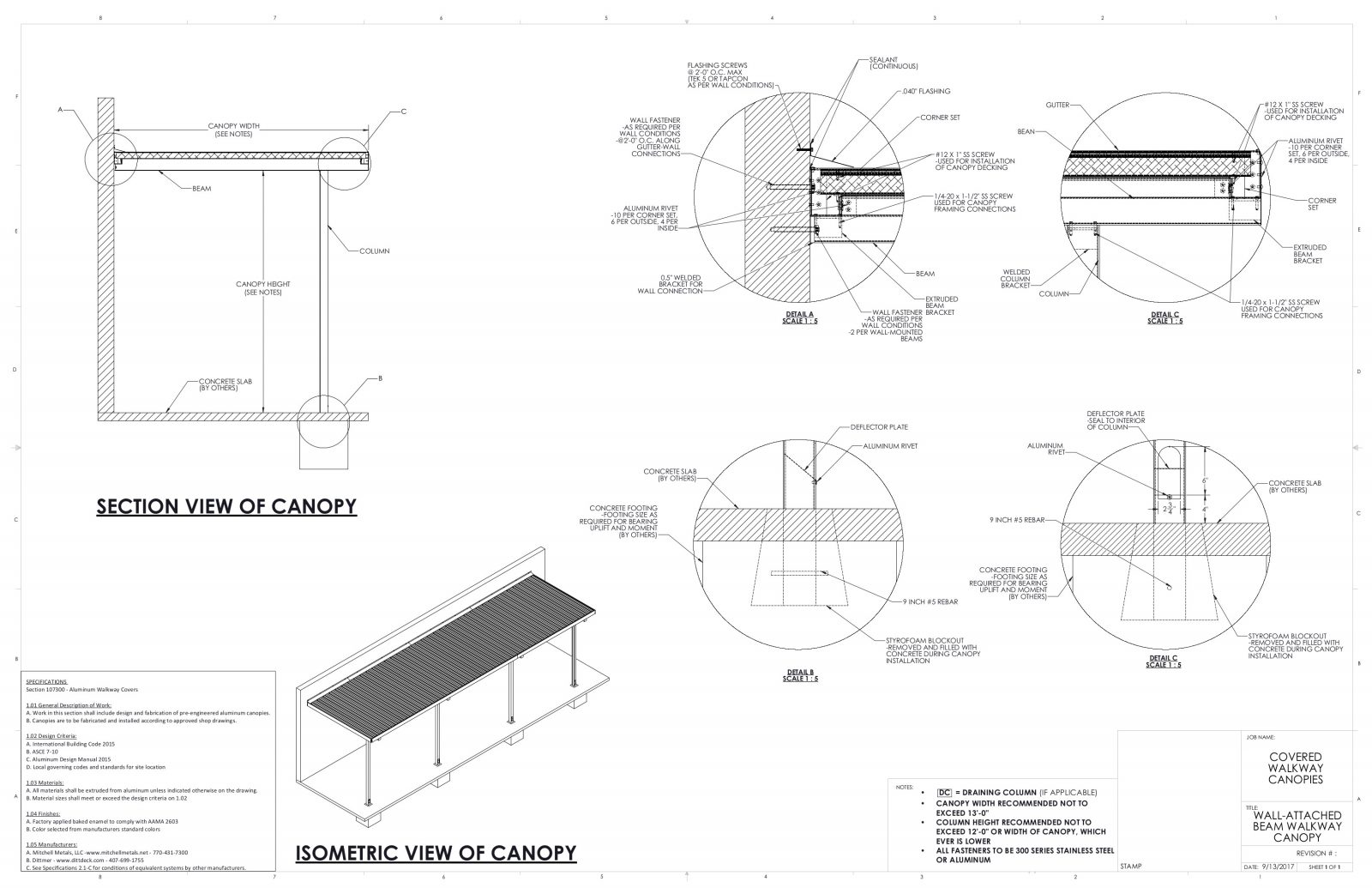

Covered Walkway Canopy Drawings Specs for Canopies Mitchell Metals

There are three main factors when designing a footing for an aluminum canopy: 1) Bearing Load 2) Wind Uplift 3) Moment created due to horizontal loading on the canopy (typically wind loading) or from a cantilevered design Bearing Load - Bearing load determines the length and width of the footing or what we call the footer "pad".

Front entry with concrete slab with steel awning and braces. Front

A canopy roof is an above-head structure often used to protect from rainfall or sunlight. It is commonly viewed as a shading connected to the outside of a structure. It is also employed as a decoration and to highlight a pathway or area of a structure.

concrete window canopy design leahmetzler

Freestanding canopy systems can be specified for numerous project applications, fabricated with a choice of materials, and engineered to meet a range of performance requirements. Unlike attached canopy systems that typically designate a building's entrances, these stand-alone structures are multifunctional.

Aluminum Canopy Systems in Texas Canopy Solutions

Method 1 Using Quick-Fix Tent Weights Download Article 1 Buy tent weight bags for an easy option. There are tent weight bags manufactured and marketed specifically for canopy tents. Usually you have to fill them with sand and then attach them to the frame and legs of your tent.

The Armadillo Vault Architecture, Canopy design, Limestone slab

Canopies are a great economical option because they only require concrete piers rather than a full slab, which can be a huge advantage for lower-budget projects. They can also be as simple or complex as required by your intended use. Here's an idea of the types of canopies you may have come across: Canopy Tents; Tube Buildings; Wood Buildings

Covered Walkway Canopy Drawings Specs for Canopies Mitchell Metals

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright.

Pin by Claudia Mendizabal on Canopies Metal awning, Canopy

A canopy is an overhead structure typically intended to provide shelter from rain or sun. It is usually seen as a covering attached to the outside of a building. It is also used for decorative purposes and to emphasize a route or part of a building. Figure-1: An Aluminium Canopy Structure

Aluminum Canopy Footings and Foundations Mitchell Metals

A cantilever slab 200 mm thick is 1.715m long, and it is supporting a blockwork load at 1.0m from the fixed end. Design the slab using the data given below; Purpose of building - Residential. f ck = 25 Mpa. f yk = 460 Mpa. Concrete cover = 25 mm. Height of block wall = 2.75 m. Unit weight of concrete = 25 kN/m 3.

Aegis Shade Structure Commercial Metal Canopy Shade structure, Canopy

The cantilevered canopy slabs were specified to have a thickness of 7 cm, concrete cover of 1.0 cm, concrete with characteristic compressive strength of 15 MPa and steel bars with yielding.

Metal Canopies Bensalem Metal

1. Entrance Canopies These canopies are installed at the entrance to a building. They might therefore allow some light in while at the same time offering protection from UV rays. An entrance canopy is useful to a building by not only highlighting the entrance location but also improving the building's aesthetics.

Another bespoke steel canopy installed in London

Chajjas and verandahs are a practical example of one way slab. 2. Two Way Slab: Two way slab is supported by beams on all the four sides and the loads are carried by the supports along with both directions, it is known as two way slab. In two way slab, the ratio of longer span (l) to shorter span (b) is less than 2.

Covered Walkway Canopy Drawings Specs for Canopies Mitchell Metals

This shows how a concrete canopy were constructed along with the managing the GI pipes that serves as scaffolding.

The Connekt Cantilever Outdoor Patio Canopy for Your Home by Canopies UK

r13 (Civil/Environmental) 31 May 20 15:09. 1. For beam-slab joint, check the development length to develop yield strength. (If saving rebars is the aim, alternate mix full and half length bars) 2. Check the torsional strength of the beam, including rotation, that would resulted in larger slab deflection. 3.

Covered Walkway Canopy Drawings Specs for Canopies Mitchell Metals

Architectural Fabrication's Atlas Canopy is the most versatile aluminum canopy system on the market. It's modular design delivers maximum flexibility in the field and the custom options allow you to design the canopy that you want. The Atlas Canopy is a field assembled product made from extruded aluminum components, including: gutter beams.

Another bespoke steel canopy installed in London

Concrete floor slab construction process includes erection of formwork, placement of reinforcement, pouring, compacting and finishing concrete and lastly removal of formwork and curing of concrete slab. Concrete Floor Slab Construction Process Assemble and Erect Formwork Prepare and Place Reinforcement Pour, Compact and Finish Concrete

Canopy Structures

Flat Slab with Column Heads - There is a considerable increase in the bending and shear forces at column heads. Therefore, we increase the section around the column.. Sunshades are sometimes called canopy slabs. They are constructed about the doors and windows to cut off the sunlight and to avoid the rainwater coming through the windows.